4.5A Monolithic LED Drivers with 3000:1 Dimming are Ideal for a Wide Range of High Power LED Applications

4.5A Monolithic LED Drivers with 3000:1 Dimming are Ideal for a Wide Range of High Power LED Applications

by

Mark Marosek

Jun 1 2007

Introduction

The LT3478 and LT3478-1 are monolithic step-up DC/DC converters specifically designed to drive high brightness LEDs with a constant current over a wide programmable range. They are extremely easy to use and include programmable features for optimizing performance, reliability, size and overall solution cost. These devices can operate in boost, buck-mode boost and buck-boost mode LED driver topologies. Depending on the topology, they can provide up to 4A of LED current, a level unmatched by other monolithic LED drivers. The LT3478 and LT3478-1 are ideal for high power LED applications, including automotive and avionic lighting, and are available in a 16-pin thermally enhanced TSSOP package with either E-grade or I-grade temperature ratings.

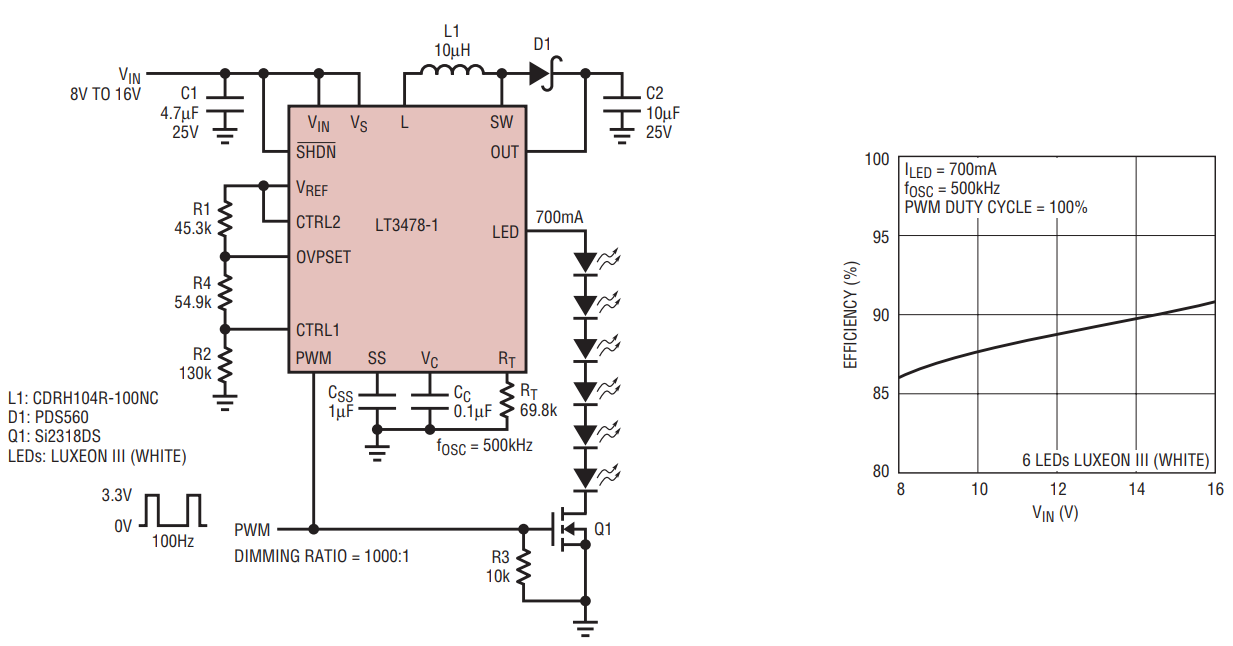

Figure 1. Automotive TFT LCD backlight, 15W, 6 LEDs at 700mA, boost LED driver.

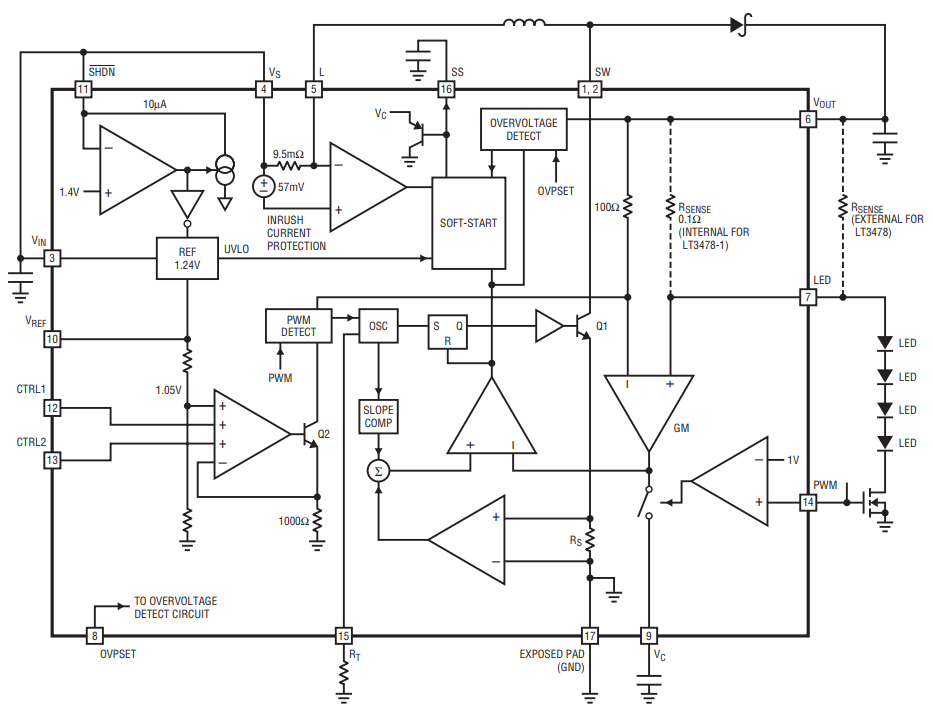

The LT3478 and LT3478-1 operate similarly to conventional current mode boost converters, but use LED current (instead of output voltage) as the main source of feedback for the control loop. The block diagram in Figure 2 shows the major functions of each part. Both parts use high side LED current sensing to extend operation to buck and buck-boost modes. The LT3478-1 saves space and cost by integrating the current sense resistor and limits maximum LED current to 1.05A. The LT3478 uses an external sense resistor to allow programming of maximum LED current up to 4A.

Figure 2. LT3478 and LT3478-1 block diagram.

Programming the LED Current for Protection and Dimming

LEDs are a desirable lighting solution in part because of their wide dimming range via simple current control. For instance, environments with the potential for very low ambient light conditions, such as automotive dashboards and airplane cockpits, require very high levels of PWM dimming. The LT3478 and LT3478-1 offer a 3000:1 PWM dimming range (preserving LED color) in addition to an optional 10:1 analog dimming range.

Current control for dimming is an important feature, but it is just as important to avoid overdriving LEDs beyond their maximum rated current. The LT3478 and LT3478-1 make it easy to set the maximum current and to derate the maximum current relative to temperature.

Maximum LED Current

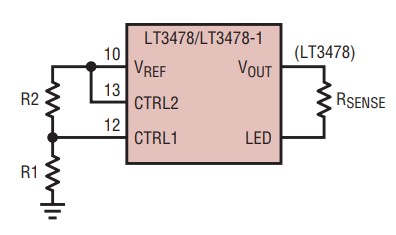

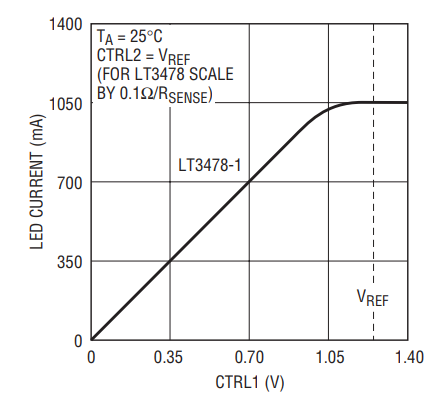

The LT3478 and LT3478-1 control maximum LED current using the voltage at the CTRL1 pin, unless the device is set to derate the maximum LED current relative to temperature (using CTRL2 pin described below). The voltage at CTRL1 pin can be set using a simple resistor divider from VREF (see Figure 3), from an external voltage source, or by connecting it directly to the VREF pin for maximum current. Figure 4 shows LED current versus CTRL1 pin voltage.

Figure 3. Programming maximum LED current.

Figure 4. LED current vs CTRL1 voltage.

Temperature-Based Derating of the Maximum LED Current

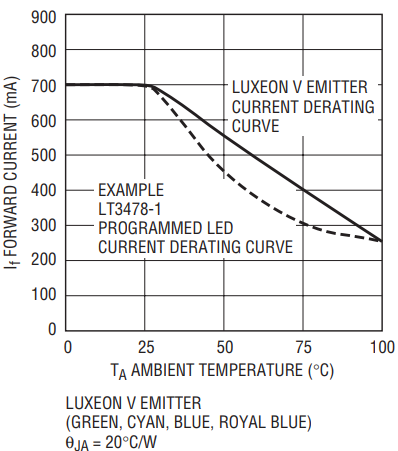

To ensure optimum reliability, LED manufacturers specify curves of maximum allowed LED current versus temperature (Figure 5). If the LED current is not derated relative to temperature, it is possible to permanently damage the LED.

Figure 5. LED current derating curve vs ambient temperature.

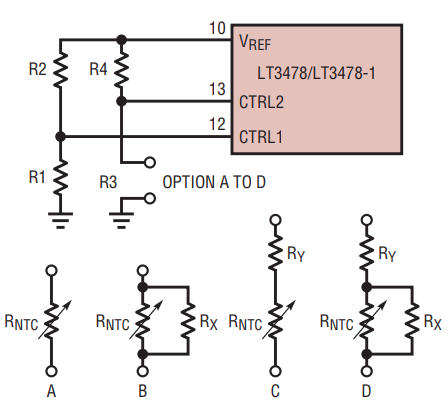

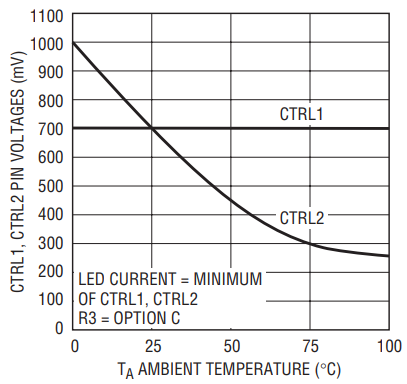

The LT3478 and LT3478-1 enable temperature derating via the CTRL2 pin. Simply connect CTRL2 to VREF via a temperature-dependent resistor divider as shown in Figure 6. As the temperature rises, the voltage at CTRL2 falls. When CTRL2 falls below CTRL1, the voltage at CTRL2 takes over in setting the maximum LED current (Figure 7).

Figure 6. Programming LED current derating curve vs temperature (RNTC located on LED’s circuit board).

Figure 7. CTRL1 and CTRL2 voltages vs temperature. The voltage at CTRL1 sets the maximum LED current until the voltage at CTRL2 falls below that of CTRL1. At that point (here at 25°C) CTRL2 takes over and derates the maximum current to rising temperature.

The temperature at which LED current begins to decrease and the rate of decrease are selectable by the resistor network/values chosen. Table 1 lists several NTC resistor manufacturers. Murata Electronics notably provides an online simulator to select the required resistor combinations as shown in Figure 6 including a catalog describing the NTC resistor specifications. Figure 5 shows an example of LT3478-1 programmed LED current falling versus temperature using the option C, shown in Figure 6, with R4 = 19.3k, RY = 3.01k and RNTC = 22k (NCP15XW223J0SRC). A more detailed description of how to determine these values by hand calculation is given in the LT3478 and LT3478-1 data sheet.

| Manufacturer | Contact |

| Murata Electronics North America | www.murata.com |

| TDK Corporation | www.tdk.com |

| Digi-Key | www.digikey.com |

Analog Dimming

Many LED applications require accurate brightness control. LED brightness can be reduced by simply decreasing the programmed LED current, but reducing the operating current of the LED changes the color of the LED. This method is known as analog dimming and is available in the LT3478 and LT3478-1 by reducing the voltage at the CTRL1 pin to as low as 0.1V (10:1 dimming from 1V). If color preservation is important, then PWM dimming is a better option.

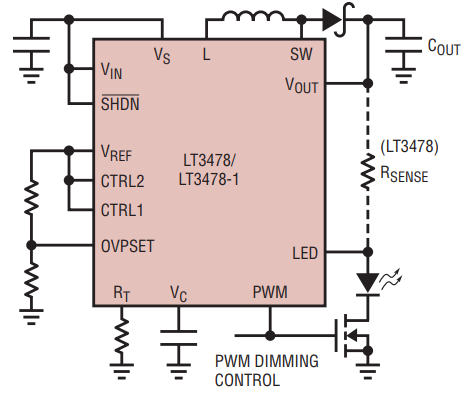

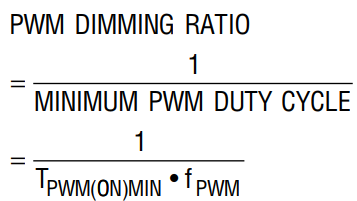

PWM Dimming

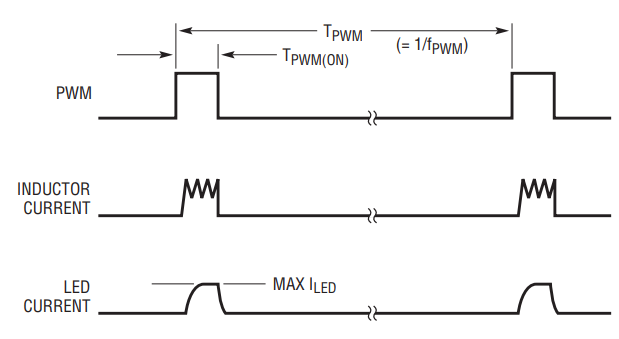

PWM dimming (Figures 8 and 9) yields high dimming ratios with no current-related LED color change. PWM dimming is implemented in the LT3478 and LT3478-1 via the PWM pin. When the PWM pin is active high (TPWM(ON)) or low, the LED current is either at its maximum or off, respectively. The LED on time, and hence the average current, is controlled by the duty cycle of the PWM pin. Because the LED is always operating at the same current (maximum set by CTRL1), and only the average current changes, dimming is achieved without changing the color of the LED.

Figure 8. PWM dimming control.

Figure 9. PWM dimming waveforms.

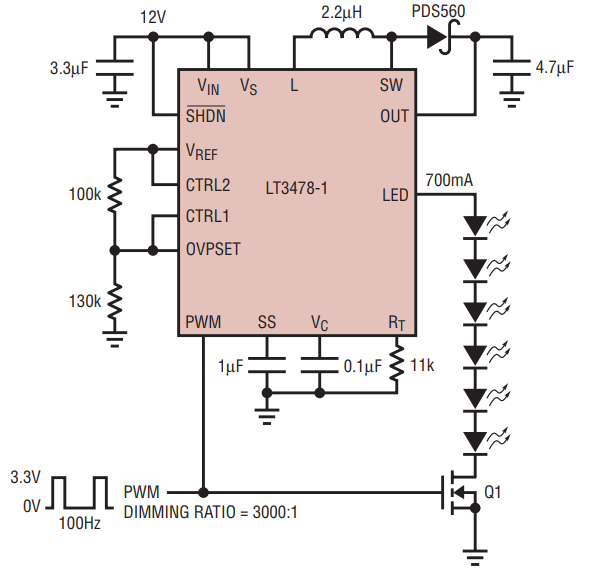

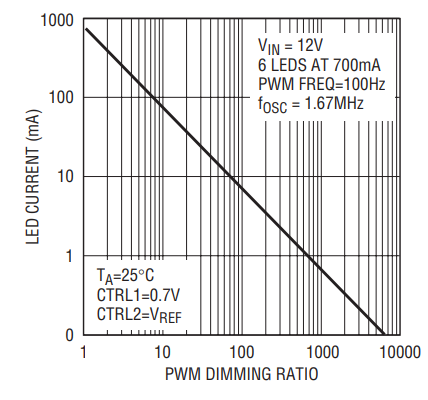

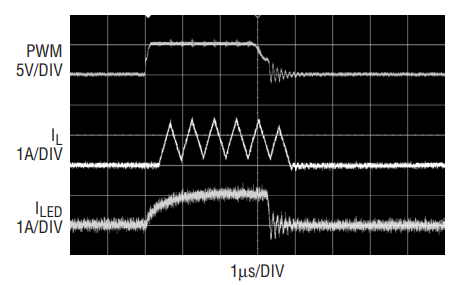

PWM dimming is not new, but the ability to achieve high PWM dimming ratios (requiring extremely low PWM duty cycles) is challenging. The LT3478 and LT3478-1 use a patented architecture to achieve PWM dimming ratios exceeding 3000:1 at 100Hz. The application circuit and waveforms shown in Figures 10, 11 and 12 show a PWM dimming ratio that can actually exceed 3000:1 if PWM on time is reduced to only 3 switching cycles (TPWM(ON) < 3.3µs for fPWM = 100Hz).

Figure 10. Boost LED driver optimized for high PWM dimming ratio (3000:1): 15W, 6 LEDs at 700mA.

Figure 11. LED current versus PWM dimming ratio for the circuit in Figure 10.

Figure 12. PWM dimming waveforms for the circuit in Figure 10.

The simplified waveforms in Figure 10 and guidelines listed below explain the relationship between PWM duty cycle, PWM frequency, PWM dimming ratio and LED current. Strategies for achieving maximum possible PWM dimming using the PWM pin fall out of the relation:

- For a PWM frequency (fPWM) of 100Hz, a PDR of 3000 implies a PWM on time of 3.3µs.

- The lower the PWM frequency, the greater the PWM dimming ratio (for a fixed PWM on time). However, there are limits to how low the PWM frequency can be operated since the human eye can see flicker below about 80Hz.

- Higher programmed switching frequency (fOSC) improves PDR but reduces efficiency and increases internal heating. In general, TPWM(ON)MIN = 3 • 1/fOSC (approximately 3 switch cycles).

- Leakage currents from the output capacitor should be minimized. The LT3478 and LT3478-1 both turn off any circuitry running from VOUT when the PWM pin is low.

- For an even wider dimming range, the PWM and analog dimming features can be combined, where TDR = PDR • ADR

where

TDR = Total Dimming Ratio

PDR = PWM Dimming Ratio

ADR = Analog Dimming Ratio

A PDR of 3000:1 and an ADR of 10:1 (CTRL = 0.1V) yields a TDR of 30,000:1.

Open LED Protection

The output voltage has a programmable maximum to avoid damaging the LEDs due to a disconnect (open LED) followed by a reconnect. During LED disconnect, the converter can go open loop and drive the output voltage so high that the internal power switch is damaged. Most LED drivers have a fixed maximum output voltage to save the switch, but this may be too high for the reconnected string of LEDs. The LT3478 and LT3478-1 provide a programmable overvoltage protection (OVP) level to limit output voltage based on the number of series connected LEDs. The OVPSET pin voltage limits the maximum output voltage, given by:

Maximum output voltage = OVPSET • 41

OVPSET voltage can be derived from VREF by it’s own resistor divider or by adding one resistor to the divider used to define CTRL1 voltage. OVPSET program level should not exceed 1V to ensure the switch voltage does not exceed 42V.

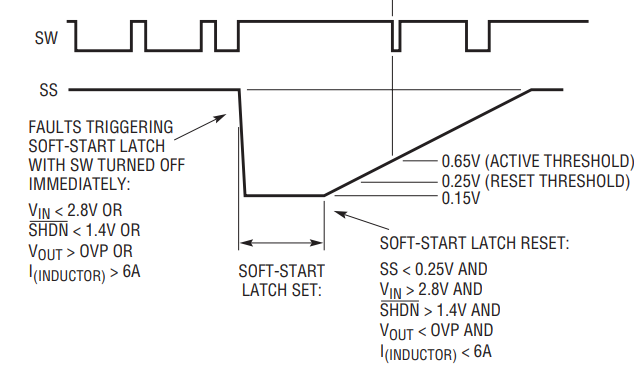

Robust Operation: Fault Detection and Soft-Start

For robust performance during hot-plugging, startup, or during normal operation, the LT3478 and LT3478-1 monitor system parameters for any of the following faults: VIN < 2.8V, SHDN < 1.4V, inductor inrush current greater than 6A, and/or output voltage greater than programmed OVP. On detection of any of these faults, the LT3478 and LT3478-1 stop switching immediately and the soft-start pin is discharged (Figure 13). When all faults are removed and the SS pin has been discharged to at least 0.25V, an internal 12µA supply charges the SS pin with a rate programmed using an external capacitor CSS. A gradual ramp up of SS pin voltage is equivalent to a ramp up of switch current limit until SS exceeds the VC pin voltage.

Figure 13. LT3478/LT3478-1 fault detection and SS pin timing diagram.

High Efficiency: Separate Inductor and IC Supplies, Programmable fOSC, 60mΩ Switch

The LT3478 and LT3478-1 can use separate supplies for the IC and the inductor to optimize efficiency and switch duty cycle range. Detection of inductor inrush current uses VS and L pins independent of the VIN supply of the IC (Figure 2). This allows VIN to be supplied from the lowest available supply (at least 2.8V) in the system to minimize efficiency lost in the power switch driver. The inductor can then be powered from a supply (between 2.8V and 36V) better suited to the duty cycle and power requirements of the LED load. The switching frequency of the power switch can be tailored to achieve the optimum inductor size and efficiency performance required for the system. The 60mΩ switch further improves efficiency by keeping switch losses to a minimum for high duty cycle operation.

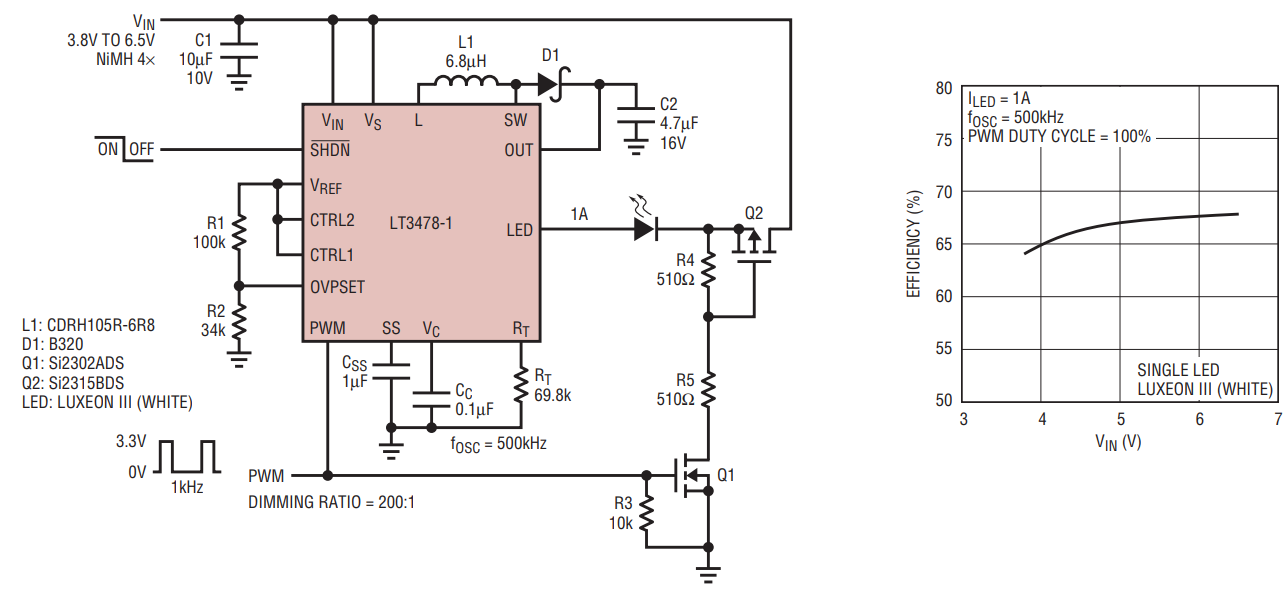

Figure 14. Portable camera flash: 4W single LED at 1A buck-boost mode LED driver.

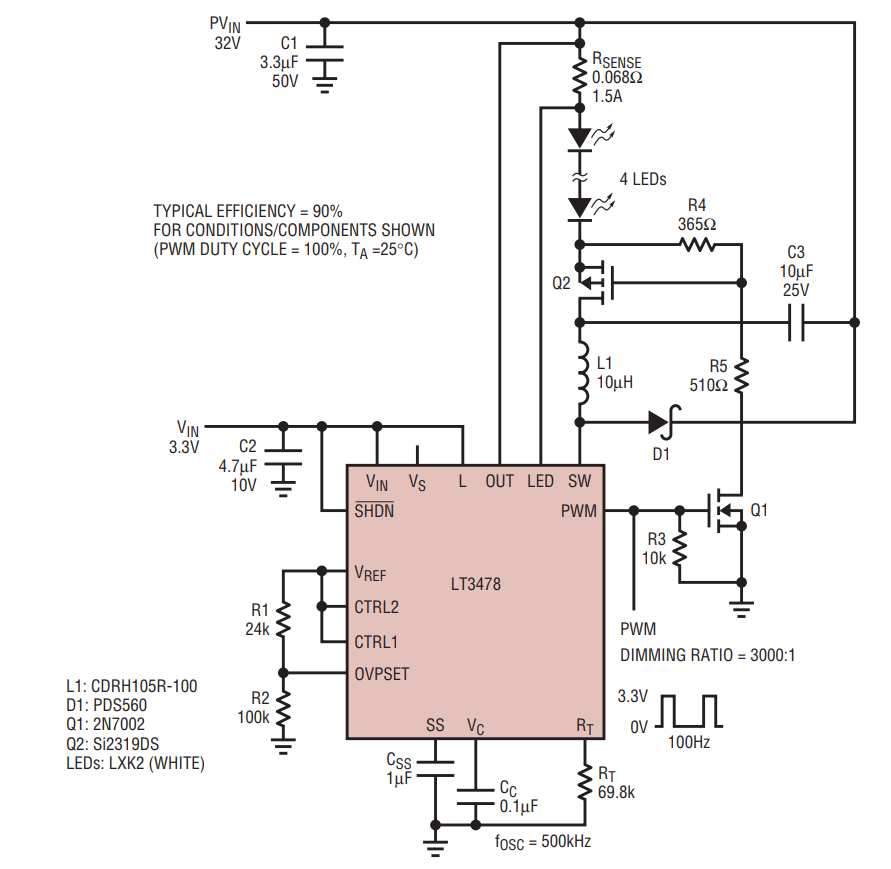

Figure 15. High powered LED lighting: 24W, 4 LEDs at 1.5A buck-boost mode LED driver.

Conclusion

The LT3478 and LT3478-1 are ideal for boost, buck or buck-boost mode LED applications requiring high LED current operation and high PWM dimming ratios. The high 4.5A peak switch current limit combined with a new patent pending PWM dimming architecture allow the LT3478 and LT3478-1 to provide high PWM dimming ratios for LED currents up to 4A.

About the Authors

Mark Marosek is a Design Engineering Manager in Analog Devices’ Power Technology group in Milpitas, CA. His interests include monolithic Boost/Inverting/SEPIC converters and Multi-String LED drivers primarily for Automotiv...