Don't Get Cold Feet with Your ASIL-B, Cold-Crank Specifications

Abstract

In this design solution, we show how a TFT-LCD display backlight can meet the automobile's toughest requirements. We demonstrate how the MAX25024 automotive backlight driver offers comprehensive diagnostics, I2C capability, and critical circuit redundancy that meet ASIL-B functional safety requirements. A clever design allows the MAX25024 to meet and exceed cold-crank specification for flicker-free automotive display operation. High integration yields a small IC, lower BOM costs, and smaller PCB size.

Introduction

New automobile models are increasingly equipped with multiple displays (Figure 1) for different functions. These “infotainment” displays may include an instrument cluster, a central information display, mirror replacement displays, and multiple rear-seat entertainment displays. Since an instrument cluster display provides relevant safety information to the driver, its electronics must be robust enough to not only withstand a harsh automotive environment (cold/hot crank, load-dump, start/stop), but also incorporate additional diagnostics required to meet ASIL (Automotive Safety Integrity Level) safety standards, have low electromagnetic interference (EMI) to reduce interference with multiple RF receivers in the vehicle, and be small enough to fit additional electronics within the same space.

This design solution reviews the main challenges of TFT-LCD backlight designs, with an emphasis on how they can meet ASIL safety standards. We also examine how they can operate without display flickering in the presence of low battery voltage (cold crank) while maintaining low EMI and a smaller size. It then introduces a TFT-LCD backlight driver IC that meets these criteria.

Figure 1. Multiple displays in the car.

Functional Safety (ASIL)

ISO (International Organization for Standardization)-26262 is one regulation that drives the requirements for functional safety. It addresses possible hazards caused by malfunctioning behavior of electrical safety-related systems, which includes the interaction of these systems. The level of functional safety required for a system is categorized by the system’s ASIL rating, which ranges from level A to level D. Level D requires the most robust system. A system’s ASIL rating is determined by the severity of potential injury, the controllability of failure, and the exposure to risks if a failure occurs. ASIL-compliant integrated circuits (ICs) include performance analysis. They use tighter protections and accuracy and have redundant references. They have fail-safe on open pins and supervisory circuitry to provide the detection, diagnosis, and validation necessary to make systems compliant. The integration of I2C communication capability into the IC facilitates control and diagnostics. Sample diagnostics include:

- Overvoltage/undervoltage detection on outputs

- Error correction on internal memory, if present

- Parity bit or CRC (cyclic redundancy check) on any interface for error detection/correction

The inclusion of these functions in a single IC enables the system to more easily reach ASIL-B level of integrity.

Cold-Crank Specification

Cold crank occurs when the ambient temperature is too low, diminishing the battery’s ability to deliver power, which causes the battery voltage to fall under the large current drawn to start the engine. The display’s electronics operation under cold crank is essential to avoid flickering.

Figure 2 displays a typical cold-crank timing diagram from ISO 16750-2. It specifies battery operation down to 2.8V (worst case) for 15ms, before recovery to a value of 6V, which could remain for a couple of seconds. Since the instrument cluster display is already operational at cranking, it is important that the TFT-LCD backlight operates correctly at this precise point.

Meeting this specification is challenging. The TFT LCD backlight driver needs a continuous 5V to drive the external boost MOSFET, but during cold crank, the battery voltage is unable to support 5V operation. A typical solution has been to pass this problem to somebody else.

Figure 2. Cold-crank detail per ISO 16750-2, Level III.

In one solution, the backlight chip has a dedicated pin so that the system designer can feed an external 5V to the driver. If an external 5V rail is not available, another IC, for example an LDO with sufficient hold-up capacity, needs to be added to the BOM. This results in extra cost and a larger PCB area. If the external rail is present but is too low, an internal charge pump is provided at the cost of extra silicon and additional external capacitors that must perform the voltage boost. In all cases, the available solutions appear at best to meet typical 3V crank specification, not the 2.8V minimum requirement.

Small Size

A high level of integration is necessary to reduce component size to fit additional electronics within the same space and to reduce cost. Advanced monolithic processes help reduce the die size and enable the use of a smaller package. The integration of additional functions on-chip reduces the overall BOM as well as minimize PCB size and cost.

Meeting the Challenge

As an example, the MAX25024 in Figure 3, is a 4-channel backlight driver IC with a boost controller for automotive displays. The four integrated LED current outputs can sink up to 150mA each, allowing the IC to power an 8in. or 10in. backlight display. The output pin (BOOST) can sustain up to 52V. The device also accepts a wide input voltage range and withstands up to 40V automotive load-dump events.

Figure 3. 4-Channel backlight Driver with boost controller.

The backlight driver IC features I2C-controlled pulse-width-modulation (PWM) dimming and hybrid dimming. In either case, the minimum pulse width is 500ns. Phase-shifted dimming of the strings and spread spectrum are incorporated for lower EMI. The IC is available in a 24-pin TQFN or 24-pin side-wettable TQFN (SWTQFN) package and operates over the -40°C to +125°C temperature range.

Meeting ASIL B Specification

Comprehensive diagnostic information is available through the MAX25024 I2C interface to ease integration in systems that require ASIL-B compliance. Features for ASIL-B systems include voltage reference redundancy, individual LED current measurement on each string, boost input current measurement, boost output voltage measurement, LED open/short detection and protection, along with boost output undervoltage and overvoltage.

Exceeds Cold Crank Specification

The MAX25024 accepts a wide 2.5V to 36V input voltage range that meets and exceeds the 2.8V minimum cold-crank specification. A unique circuit architecture (see Figure 4) allows the IC to achieve this level of performance. An on-board LDO, normally powered by the battery (IN pin), provides 5V to the driver (DR). When an undervoltage spike is sensed, the LDO input is switched to the output (BOOST pin). The output capacitor (COUT) now can sustain the LDO operation during the 15ms specified cold crank.

Figure 4. 5V LDO bias during cold crank.

Figure 5 shows a 2.5V, 100ms cold-crank spike (see yellow curve) that doesn’t affect the output voltage (VBOOST) and LED current. Accordingly, the fault flag (FLTB) remains de-asserted.

Figure 5. Cold-crank test: 9 LED/String, 100mA/String × 4, 400kHz, VIN = 2.5V (100ms).

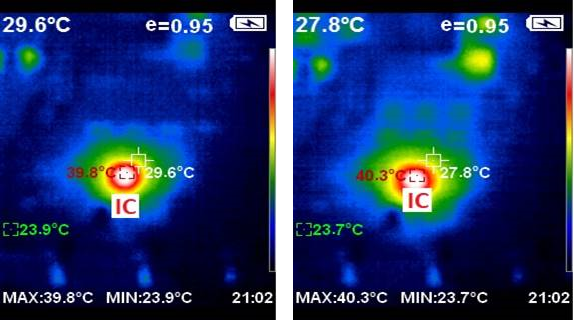

The on-board LDO consumes minimal power and the package’s low thermal resistance assures a very low junction temperature. In Figure 6, the picture on the left shows an IC temperature of 39.8°C before the crank, with a 12V battery voltage. The picture on the right shows an IC temperature of 40.3°C immediately after a 100ms crank down to 2.5V, for a net temperature rise of less than 1°C.

Figure 6. IC temperatures with 9 LED/String, 100mA/String × 4, 400kHz before and after a 100ms crank.

Low EMI

The MAX25024 is also tested for electromagnetic radiation according to EMI CISPR25 Class 5 specifications. As an example, Figure 7 shows one of many EMI tests that was performed with a 200MHz to 1GHz log-periodic (horizontal) antenna. The IC’s emission levels are well below the limit.

Figure 7. Meeting the CISPR25 class 5 EMI specification.

Reduced Size and Cost

A high level of integration fits multiple functions in a small 4mm × 4mm TQFN package. Competitor devices are housed in a 7mm × 7mm package, which is a 3× increase in PCB size occupancy. The external NMOS switch disconnects the battery from the output in the case of a shorted output. The NMOS is turned on by means of an integrated charge pump, avoiding the use of extra pins or external capacitors. A small and cost-effective NMOSFET, as opposed to the large PMOSFET found in competitor solutions, is used here to minimize BOM size and cost. These advantages yield a PCB size that is 45% smaller than other solutions.

Conclusion

TFT-LCD displays are ubiquitous in modern automobiles. Their backlight must operate under harsh conditions, meet functional safety requirements, and be small in size. We discussed the shortcomings of existing solutions and presented a new cost-effective backlight driver IC, the MAX25024, that not only meets ASIL-B functionality, but exceeds cold-crank specification and has low EMI, all in a small package.

Learn More

Back to Black with Backlight Local Dimming

How to Power the Automotive TFT-LCD Displays of the (Not so Distant) Future

A similar version of this design solution originally appeared in Electronic Products on June 25, 2020.