Design Note 111: LT1510 High Efficiency Lithium-Ion Battery Charger

The LT1510 current mode PWM battery charger is the simplest, most efficient solution for fast charging modern rechargeable batteries including lithium-ion (Li-Ion), nickel-metal-hydride (NiMH) and nickelcadmium (NiCd) that require constant current and/or constant voltage charging. The internal switch is capable of delivering 1.5A DC current (2A peak current). The onboard current sense resistor (0.1Ω) makes the charge current programming very simple. One resistor (or a programming current from a DAC) is used to set the charging current to within 5% accuracy. With 0.5% reference voltage accuracy, the LT1510 16-lead S package meets the critical constant voltage charging requirement for lithium cells.

The LT1510 can charge batteries ranging from 1V to 20V. A blocking diode is not required between the chip and the battery because the chip goes into sleep mode and drains only 3μA when the wall adaptor is unplugged. Soft start and shutdown features are also provided.

Lithium-Ion Battery Charger

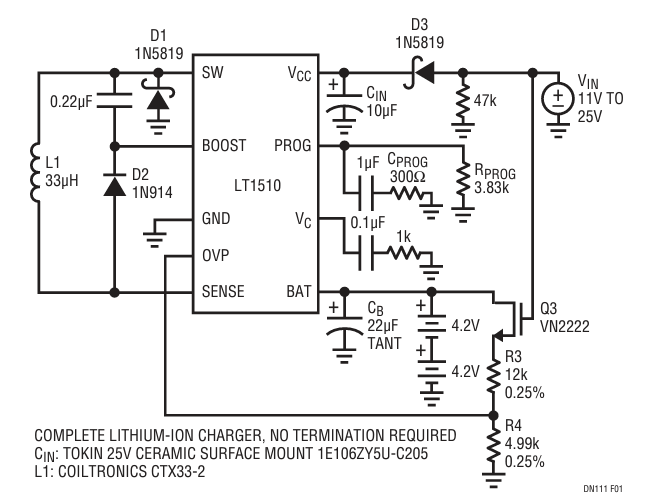

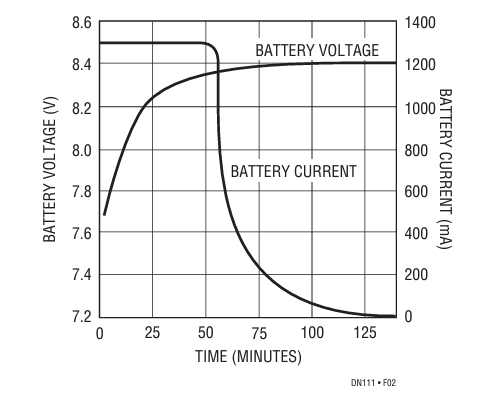

The circuit in Figure 1 uses the 16-lead LT1510 to charge lithium-ion batteries at a constant 1.3A until battery voltage reaches 8.4V set by R3 and R4. The charger will then automatically go into a constant voltage mode with current decreasing toward near zero over time as the battery reaches full charge. This is the normal regimen for lithium-ion charging, with the charger holding the battery at “float” voltage indefinitely. In this case, no external sensing of full charge is needed. Figure 2 shows typical charging characteristics.

The battery DC charging current is programmed by a resistor RPROG (or a DAC output current) at the PROG pin. High DC accuracy is achieved with averaging capacitor CPROG. The basic formula for full charging current is:

Approximately 0.25mA flows out of the BAT pin at all times when adapter power is applied. Therefore, to ensure a regulated output even when the battery is removed, the voltage divider current should be set at 0.5mA. Q3 is used to eliminate this current drain when adapter power is off, with a 47k resistor to pull its gate low.

With divider current set as 0.5mA, R4 = 2.465/0.5mA

= 4.93k, let R4 = 4.99k:VIN has to be at least 3V higher than battery voltage and between 8.5V to 25V.

Lithium-ion batteries typically require float voltage accuracy of 1% to 2%. The LT1510 OVP voltage has 0.5% accuracy at 25°C and 1% over full temperature. This may suggest that very accurate (0.1%) resistors are needed for R3 and R4. Actually, in float mode the charging currents have tapered off to a low value and the LT1510 will rarely heat up past 50°C, so 0.25% resistors will provide the required level of overall accuracy.

Thermal Calculations

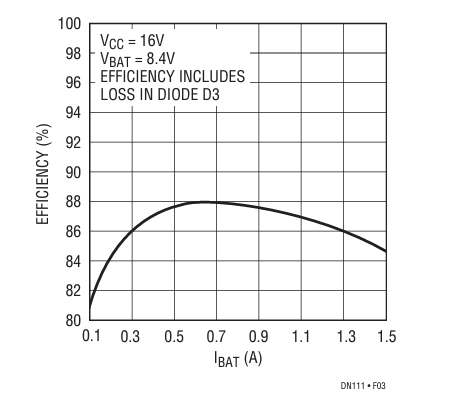

Although the battery charger achieves efficiency of approximately 86% at 1.3A, a thermal calculation should be done to ensure that junction temperature will not exceed 125°C. Power dissipation in the IC is caused by bias and driver current, switch resistance, switch transition losses and the current sense resistor. The 16-leadSO, with a thermal resistance of 50°C/W, can provide a full 1.5A charging current in many situations. Figure 3 shows the efficiency for charging currents up to 1.5A.

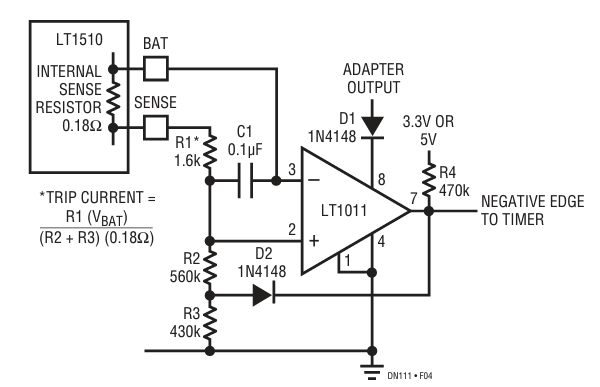

Some battery manufacturers recommend termination of constant voltage float mode 30 to 90 minutes after charging current has dropped below a specified level (typically 50mA to 100mA). Check with the manufacturers for details. The circuit in Figure 4 will detect when charging current has dropped below 75mA. This logic signal is used to initiate a timeout period, after which the LT1510 can be shut down by pulling the VC pin low with an open collector or drain. Some external means may be used to detect the need for additional charging or the charger may be turned on periodically to complete a short float voltage cycle. The current trip level is determined by the battery voltage, R1 through R3, and the internal LT1510 sense resistor (≈ 0.18Ω pin-to-pin). D2 generates hysteresis in the trip level to avoid multiple comparator transitions. R2 and R3 are chosen to total about 1M to minimize battery loading. D2 is assumed to be off during high current charging when the comparator output is high. To ensure this, the ratio of R2 to R3 is chosen to make the center node voltage less than the logic supply. R4 is somewhat arbitrary and does not affect trip point. R1 is adjusted to set the trip level.