How to Optimize Performance When Using Synchronous Rectification in Nonisolated DC-DC Converters

How to Optimize Performance When Using Synchronous Rectification in Nonisolated DC-DC Converters

Abstract

This application note explains the advantages along with some of the extra considerations needed in circuit design to achieve the best performance when implementing synchronous rectification in nonisolated DC-DC converters.

A similar version of this application note appeared in Power Electronics on December 8, 2017.

In the most basic diagrams of nonisolated DC-DC converters, you’ll typically see two ideal switches and an energy storage inductor. In early designs, engineers quickly realized that one switch could be replaced by a low-cost diode; it turned itself on naturally at the right instant through commutation, when the inductor reverses its voltage during the main switch off-time and forward-biases the free-wheeling diode D1 (see Figure 1, left).

Figure 1. Diode compared with synchronous rectification.

This approach is great in terms of simplicity. And while the diode does drop some voltage while it is circulating output current, this is still a small percentage of power loss when the output voltage is relatively high.

However, in an effort to increase operating speed while maintaining low dissipation, output voltages have plummeted to below 1V for processors and other ICs. The irony in this is, the efficiency problem is now back to the DC-DC converter power source, since the diode voltage drop has become a much larger proportion of the output voltage. A 1V diode drop with a 1V output dissipates the same amount of power that the converter is delivering to the load during the off-time (1 - D). The converter, therefore, has approximately only 50% efficiency during this period. How this low efficiency affects the overall converter efficiency depends on the input/output voltage ratio and the efficiency during the on-time. Higher DC-DC input-output voltage differentials worsen the problem with the associated longer off-times.

An Ideal Switch with Minimal Voltage Drop

A solution to this dilemma has been to try to get back to the ideal switch for SW2 with minimal voltage drop. Bipolar transistors presented an option, but a MOSFET is the obvious choice. Initially, these were limited to lower current applications as their losses are proportional to current squared, while diodes were simply proportional. These days, RDS(ON) values are so low that high current applications are viable as well. MOSFET total gate-charge values (QG) have also dropped, significantly reducing drive losses and enabling higher operating frequencies. MOSFETs are also advantageous because they can be paralleled as discrete devices or multiple die in ICs, providing more than proportionally better performance with lower net on-resistance and lower die temperatures. They have a positive temperature coefficient for RDS(ON) so they naturally share current. Diodes, on the other hand, can be paralleled but without guaranteed current sharing. A MOSFET, of course, has to be actively driven on and off but simply in direct antiphase to the main switch with a ground referenced signal, which is easy to integrate into control ICs. One important note: the two switches should never be on together, not even momentarily, as this would be a direct short across the input supply with potential damage to semiconductors and PCB traces.

In practice, a dead-time between on-periods of the switches is imposed by the control IC to guarantee no shoot-through. During the dead time, commutation still happens with the intrinsic body diode of the MOSFET. This diode usually has a relatively high forward voltage drop and long reverse recovery time, so it can produce significant dissipation if the dead time is allowed to be too long. These problems can be minimized via tight control of timing within the control IC. Another work-around, though it would add cost to the solution, is to fit a Schottky diode in parallel with the MOSFET so it conducts before the body diode.

Figure 1 provides a simple comparative example. Here, power losses in a DC-DC converter producing 5V/2.5A from 24V are compared using a diode and synchronous rectifier. Even with 5V out, the advantages are clear; losses are more than halved from 0.99W to 0.4W in the rectifier. Even if a Schottky diode is used, the gain is still significant. With lower output voltages the improvement is more dramatic still. The result is that the lower dissipation synchronous rectifier MOSFET can now be integrated into a control IC such as the MAX17503 with lower overall converter temperature rise, 30℃ in this example. Alternatively, for the same temperature rise, a smaller solution is possible.

Conducting in Both Directions

Another area where a synchronous rectifier MOSFET differs from a diode is that it can conduct in both directions when turned on. This isn’t a problem under normal operation. However, consider the scenario where the load requires multiple sequenced voltage rails and our DC-DC converter has to turn on last when there is already some voltage on the load, perhaps coming through a sneak path. DC-DC converters normally have a soft start where the duty cycle ramps up to its operating point after power-up. This means initial short on-pulses and long off-times when the synchronous MOSFET conducts. The prebiased load initially has a higher voltage than the DC-DC output, so current flows back into the DC-DC converter and MOSFET, perhaps preventing the DC-DC controller from starting up correctly.

This can be resolved by disabling synchronous rectification during the startup phase with the MOSFET’s body diode forming the "free-wheel" diode function. Again, this is easily incorporated into control IC functionality. The extra dissipation during startup is insignificant.

Light-Load Operation

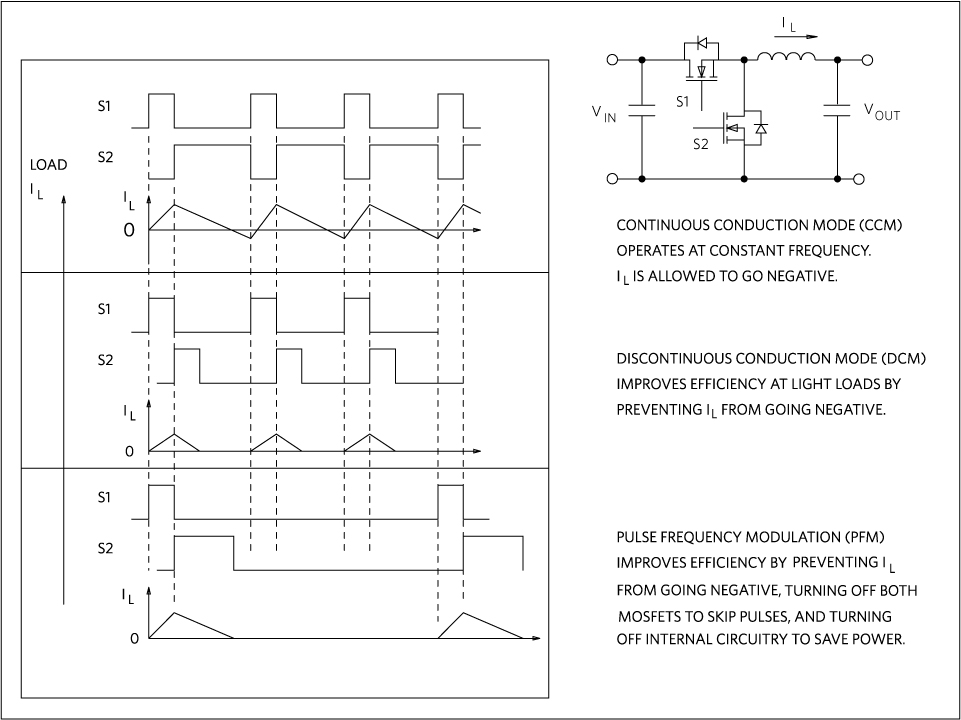

The MOSFET's ability to conduct in both directions affects light-load operation and can be beneficial. Looking at the inductor current in Figure 2, at higher loads (upper traces) you see the familiar shape of an average DC current IO(AVG) and a ripple current whose peak-to-peak amplitude is set by the inductor value and duty cycle. As the load goes to lower values (lower traces), the valley of the ripple current touches zero at the point where the load is half the peak-to-peak value of the ripple current. As the load decreases further, with diode rectification, the current stops until some point after the next on-period commences, where the current rises above zero. This is discontinuous conduction mode (DCM). For a MOSFET synchronous rectifier, current can flow in both directions, thus remaining in continuous conduction mode (CCM).

Figure 2. Continuous conduction via synchronous rectification.

The DC-DC converter can continue to supply power and regulate in DCM, but the transfer function changes. A loop optimized for bandwidth and transient performance in CCM is generally suboptimal in DCM with sluggish response. In CCM, the output voltage is simply related to duty cycle D by:

For a buck converter operating in DCM, the situation is far more complex, where:

In this scenario, the duty cycle changes in proportion to the square root of load current. As a result, this provides a more complex transfer function for the converter power stage. D also now depends on actual inductance, L, and switching frequency, fSW. From a performance standpoint, remaining in CCM with synchronous rectification is clearly a better option. In fact, modern buck converter designs deliberately allow high ripple current values since loop performance won’t be an issue. This allows smaller values of inductors with benefits in cost and large-signal slew-rate ability.

When light-load efficiency is a design constraint, allowing discontinuous mode operation by disabling the synchronous rectifier and losing the switching and negative current conduction losses in the MOSFET can be a good choice. Control ICs can provide this option and others as well; for example, the IC can force a pulse-skipping mode at light loads where the on-time is kept constant. In this mode, known as pulse frequency modulation (PFM), regulation is achieved by effectively varying the switching frequency at light load so that just sufficient energy is passed to the output to keep the voltage constant. Switching losses are proportional to frequency, so at light load these are reduced, gate-drive power goes down and, as both switches can be off for long periods, some circuitry internal to the IC can be disabled for the duration, saving even more power.

In Figure 3, you'll see the waveforms in the various modes.

Figure 3. CCM, DCM, and PFM operation modes.

Synchronous Rectification with Boost Converters

Using synchronous rectification with boost and buck-boost converters is not quite so straightforward. Since the rectifier doesn’t have a grounded terminal, the MOSFET drive wouldn’t be ground referenced. A possibly more problematic occurrence is that in DCM, the control IC isn't necessarily aware that the stored energy has all been transferred. When this occurs at some light load before the end of the switching cycle, a diode would simply stop conducting. A MOSFET, on the other hand, would start conducting in reverse. In a boost converter, this would connect the output back to the input, draining the output capacitor and dropping the output voltage. Schemes to avoid this are possible by forcing CCM with variable frequency modes or even detecting the reverse current flow through the MOSFET and cutting its drive. The issue is not significant, though, as boost converters are by definition producing higher voltages where the benefits of synchronous rectification are less important.

Synchronous rectifiers can also be used in the isolated versions of buck and boost converters where you have a choice of simple self-driven circuits or more complex but controlled versions where the drive signals cross the isolation barrier. Learn more about this topic by watching the video, "Introduction to Control Algorithms in Switching Regulators" hosted by Bob Mammano, the father of the first switch-mode power supply. This segment is part of a series of power system design videos that cover various aspects of power-switching technology.