Design Note 548: 60V Buck-Boost LED Driver with Up to 98% Efficiency Has Internal PWM Dimming and Spread Spectrum

Introduction

Synchronous buck-boost converters with four power switches can deliver very high efficiency while providing both step-up and step-down DC/DC conversion. Combining the capabilities of two separate converters (buck and boost) has the advantage of reduced solution size and cost. Four-switch converters should be able to operate with just two switches for highest efficiency when only step-up or step-down conversion is needed. However, they must also be able to utilize four-switch operation as VIN and VOUT approach each other, and to transition gracefully between these regions of operation. Combining control loops for two-switch boost, two-switch buck, and four-switch operation, and designing nearly flawlessly transitions between these regions of operation has its challenges. However, the next generation of buck-boost converters masters these challenges and more.

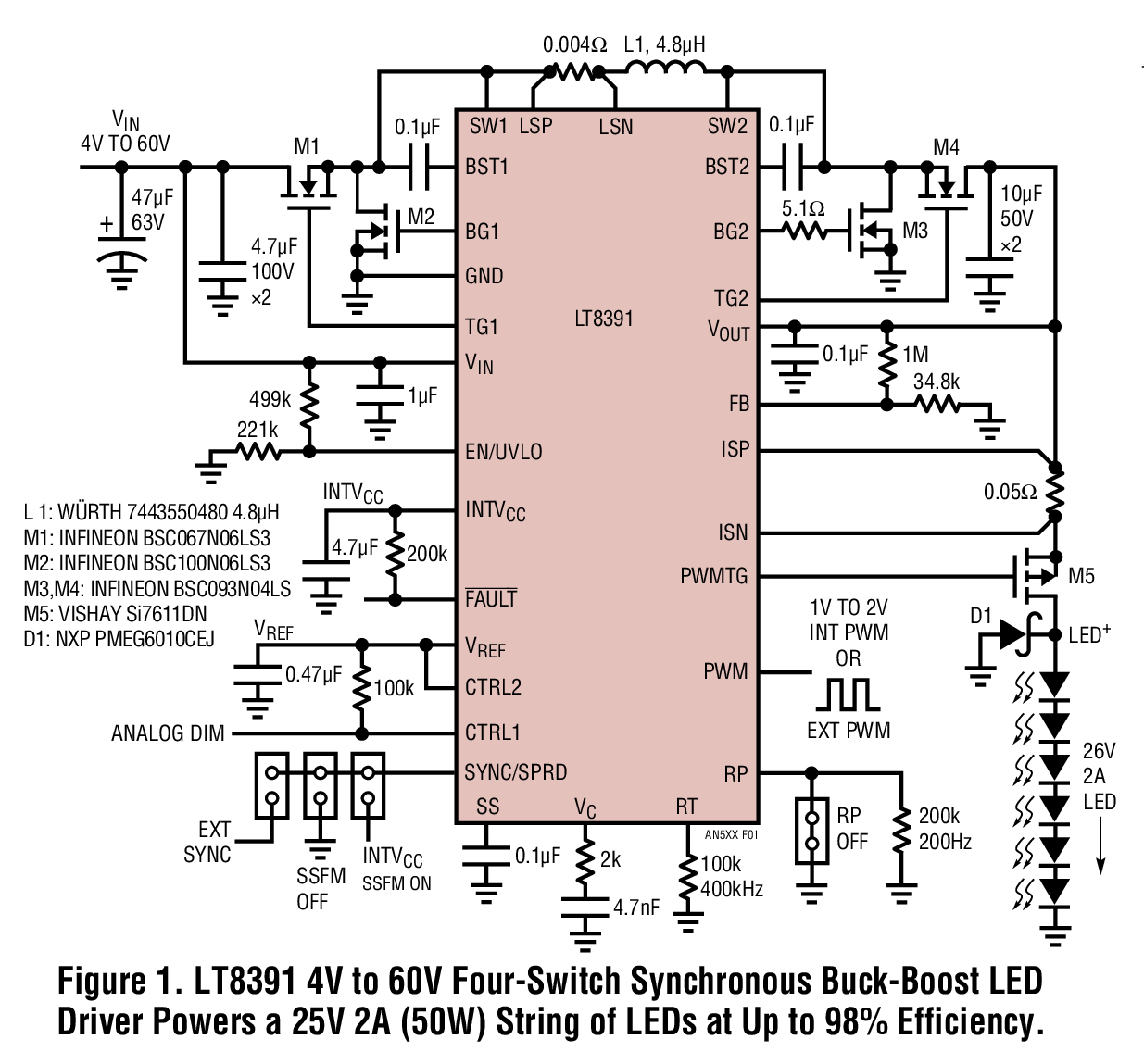

The LT8391 60V four-switch buck-boost LED driver is designed to drive high power LEDs up to 250W and to flawlessly transition between two-switch boost, four-switch buck-boost, and two-switch buck regions of operation. A patent pending four-switch buck-boost current-sense resistor control scheme provides a simple, yet masterful method for the IC to run in peak current mode control in all regions of operation with a single sense resistor. This new generation buckboost LED driver features spread spectrum frequency modulation and internally generated PWM dimming, which work together. The LT8391 has flicker-free PWM dimming with both internal and external PWM dimming, even when spread spectrum is turned on (another patent pending technique).

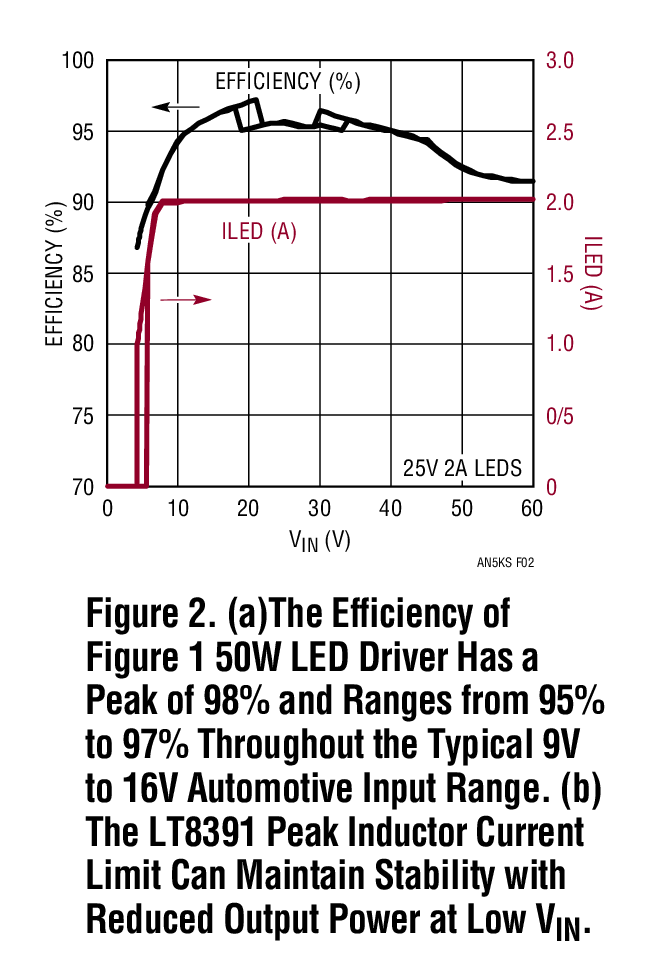

98% Efficient Buck-Boost LED Driver

The LT8391 high power buck-boost LED driver in Figure 1 drives 25V of LEDs at 2A from a wide input voltage range. Efficiency can reach 98% at its highest point. Over the typical automotive battery range of 9V to 16V, the converter operates between 95% and 97% efficiency. With a single high power inductor, the temperature rise is low, even at 50W. At 12VIN, no component rises more than 25°C. At 6VIN, the hottest component rises less than 50°C with a standard 4-layer PCB and no heat sink or air flow. This leaves room to increase the power output of the converter, making hundreds of watts possible.

The LT8391 operates down to 4VIN, where IIN can get very high. The LT8391 is designed to either handle very high input currents or use its peak switch current limit to operate with stability at low VIN while reducing output power. This allows the converter to run through automotive cold-crank voltages or other drops in VIN without an increase in power component size or cost.

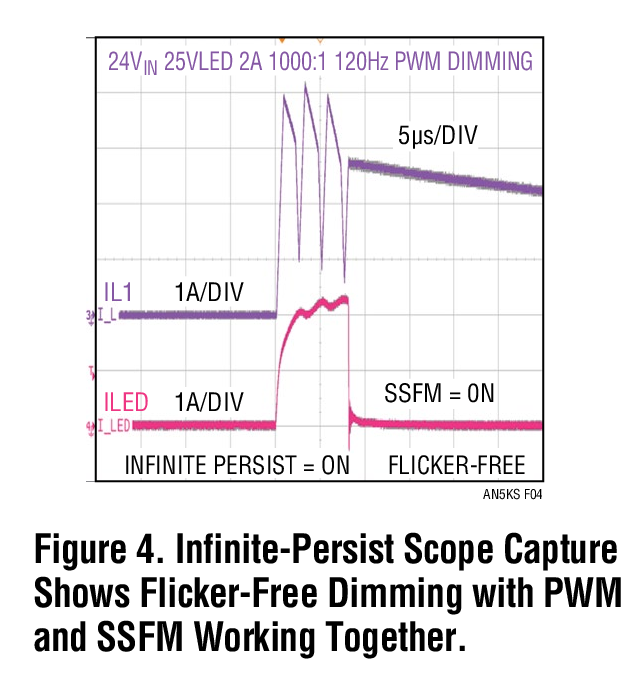

The LT8391 can achieve 1000:1 PWM dimming with no flicker. The high side PWM (TG) MOSFET PWM dims a grounded LED string. It also acts as an overcurrent disconnect during short-circuits.

Internally Generated PWM Dimming

The LT8391 has both standard external PWM dimming and internally generated PWM dimming. LT8391’s unique internal PWM dimming eliminates the need for components such as clocking devices and microcontrollers to generate accurate PWM brightness control at ratios as high as 128:1. The IC’s internally generated PWM frequency, such as 200Hz, is set by a simple resistor on the RP pin. A voltage between 1V and 2V on the PWM pin determines the PWM duty cycle. The duty cycle of the internal dimming is chosen as one of 128 steps and internal hysteresis prevents duty cycle chatter. The <±1% accuracy of internally generated PWM dimming is the same for all regions of operation.

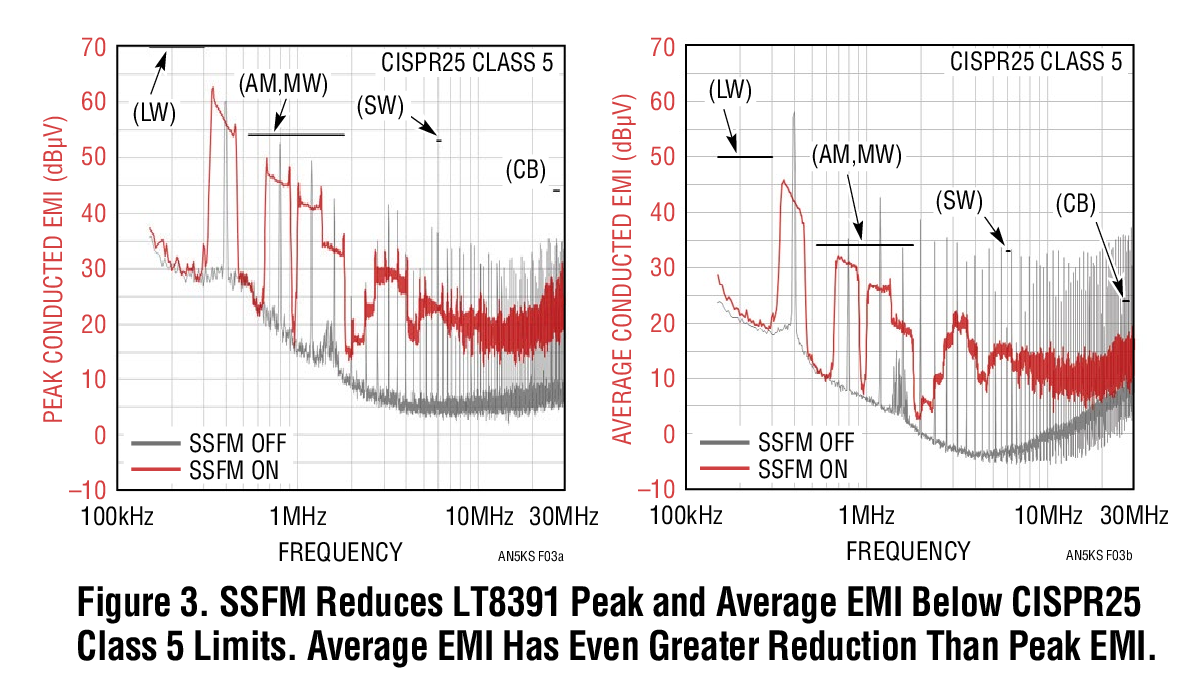

Spread Spectrum Frequency Modulation (SSFM) Reduces EMI

SSFM reduces EMI in switching regulators. Although the switching frequency is most often chosen to be outside the AM band (530kHz to 1.8MHz), unmitigated switching harmonics can still violate stringent automotive EMI requirements within the AM band. Adding SSFM significantly reduces EMI both within the AM band as well as other regions.

When activated, SSFM drops the LT8391’s 50W LED driver EMI below both the peak and average EMI requirements of CISPR25 (Class 5) in the AM band. CISPR25 average EMI limits are 20dBμV lower in some places than peak limits, and harder to pass for switchers. For this reason, LT8391’s novel SSFM reduces average EMI more than its peak. There is 18dBμV or more reduction of average EMI and about 5dBμV of peak EMI reduction.

In some LED converters, SSFM and PWM dimming do not work together without causing flicker. SSFM, a source of changing switching frequency, may appear as noise to the outside world in order to spread EMI lower than its non-spread peak values, but it can work with PWM dimming for flicker-free operation. Linear’s patent pending PWM dimming and SSFM operation runs both functions simultaneously with flicker-free operation, even at high dimming ratios. At 1000:1 PWM dimming with external PWM and at 128:1 internally generated PWM, SSFM operates with flicker-free LED current.