AN-030: Three Phase Stepper with TMC5062

Abstract

The TMC5062 supports driving up to two three phase stepper motors. This application note describes the additional register settings available in the TMC5062 for three phase motor operation.

Additionally, it covers the option bits to change the microstep resolution for TMC5062 and TMC5031 (see Table 1.2). This allows increasing the effective acceleration rate, e.g., a half microstep gives double velocity and acceleration rate.

Three Phase Motor Operation

The TMC5062 is prepared to drive three phase motors. However, three phase motors are not often found in stepper drives, but they provide an additional smoothness at low velocity operation due to a lower intrinsic detent torque. The following chapters show additional information adding to the TMC5062 datasheet in order to provide the required settings. For three phase motors, the TMC5062 also supports stallGuard as well as coolStep, but dcStep is only available with two phase steppers.

TMC5062 three phase section is identical to the TMC389.

Three Phase Motor Application

In a three phase motor application, only three half bridges and a single sense resistor are required to drive a stepper motor. One or both motor drivers can be configured for driving a three phase motor. It is important to match the external wiring before switching on this option of the power driver stage. Do not enable a two phase setting with a three phase motor.

Figure 1.1 Connecting a three phase motor.

| Pin | Number | Type | Function |

| O2A1 |

14 |

O (VS) |

Motor 2 A1 output (stepper motor coil A), or three phase stepper motor U output. |

| BR2A |

15 | Motor 2 bridge A negative power supply and current sense input. Provide external sense resistor to GND. | |

| O2A2 |

16 |

O (VS) |

Motor 2 A2 output (stepper motor coil A), or three phase stepper motor V output. |

| VS | 17, 19 | Driver 2 positive power supply. Connect to VS and provide sufficient filtering capacity for chopper current ripple. | |

| GNDP | 18 | GND | Power GND for driver 2. Connect to GND. |

| O2B1 | 20 | O (VS) |

Motor 2 B1 output (stepper motor coil B), or three phase stepper motor W output. |

| BR2B | 21 | Motor 2 bridge B negative power supply and current sense input. Provide external sense resistor to GND. Connect to BR2A for three phase motor operation. |

|

| O2B2 | 22 | Motor 2 B2 output (stepper motor coil B), unused for three phase stepper motor. |

|

| O1B2 | 39 | Motor 1 B2 output (stepper motor coil B), unused for three phase stepper motor. |

|

| BR1B |

40 | Motor 1 bridge B negative power supply and current sense input. Provide external sense resistor to GND. Connect to BR1A for three phase motor operation. |

|

| 01B1 | 41 | O (VS) |

Motor 1 B1 output (stepper motor coil B), or three phase stepper motor W output. |

| VS |

42, 44 |

Driver 1 positive power supply. Connect to VS and provide sufficient filtering capacity for chopper current ripple. |

|

| GNDP |

43 |

GND |

Power GND for driver 1. Connect to GND. |

| O1A2 |

45 |

O (VS) |

Motor 1 A2 output (stepper motor coil A), or three phase stepper motor V output. |

| BR1A |

46 |

Motor 1 bridge A negative power supply and current sense input. Provide external sense resistor to GND. |

|

| O1A1 |

47 |

O (VS) |

Motor 1 A1 output (stepper motor coil A), or three phase stepper motor U output. |

Register Set to support Three Phase Motors

Programmable microstep shapes allow optimizing the motor performance. Both drivers can drive a two- or a three phase stepper motor. In order to drive higher current motors, a parallel mode allows double current for a single driver, by paralleling both output power stages. In order to operate a three phase motor, the MSLUTSTART entry has to be re-initialized to fit the 120° phase shift required for a three phase motor, rather than 180° phase shift for a two phase motor. The settings most important for a three phase motor are highlighted.

| MOTOR DRIVER REGISTER SET (MOTOR 1: 0X60 to 0X6F, MOTOR 2: 0X70 to 0X7F) |

|||||

| R/W |

Addr |

n | Register | Description / bit names |

Range [Unit] |

| W |

0x69 0x79 |

8 + 8 |

MSLUTSTART |

bit 7 to 0: START_SIN Attention: Default values are for two phase motor, initialize before first motion with three phase motor! |

START_SIN reset default =0 (2ph/3ph) START_SIN90_120 reset default =247 (2ph) Set to 214 for 3 phase motor when using default table. |

| R | 0x6A 0x7A |

10 | MSCNT |

Microstep counter. Indicates actual position in the microstep table for CUR_A. CUR_B uses an offset of 256 (2 phase motor) resp. 171 (3 phase motor). Hint: Move to a position where MSCNT is zero before re-initializing MSLUTSTART or MSLUT and MSLUTSEL. |

|

| 0X6C, 0X7C: CHOPCONF – CHOPPER CONFIGURATION 31 to 16 |

|||

| Bit |

Name |

Function | Comment |

| 31 | ph3sel |

1: 3 phase motor |

ph3sel=0: 2 phase motor |

| 30 | diss2g |

short to GND protection disable | 0: Short to GND protection is on 1: Short to GND protection is disabled |

| 29 | 0 | Do not use | Set 0 |

| 28 | intpol16 | 16 microsteps with interpolation |

1: In 16 microstep mode, the microstep resolution becomes extrapolated to 256 microsteps for smoothest motor operation |

| 27 | mres3 |

MRES micro step resolution |

%0000: Native 256 microstep setting. Normally use this setting when the IC is operated with the internal ramp generator. |

| %0001 to %1000: 128, 64, 32, 16, 8, 4, 2, FULLSTEP Reduced microstep resolution. The resolution gives the number of microstep entries per sine quarter wave. Please take care to switch at certain microstep positions, when switching to a low resolution. The switching position determines the sequence of patterns. step width=2^MRES [microsteps] Attention: Optional use to increase effective acceleration in high acceleration applications, only. A 128 microstep setting will double the acceleration range, as the motor operates with double velocity at the same setting as with 256 microsteps. Use carefully. Does not integrate with dcStep. |

|||

| 26 | mres2 |

||

| 25 | mres1 |

||

| 24 | mres0 |

||

| 23 | sync3 | SYNC PWM synchronization clock |

ph3sel=0, only |

| 22 | sync2 | ||

| 21 | sync1 | ||

| 20 | sync0 | ||

| 19 | vhighchm |

high velocity chopper mode | ph3sel=0, only |

| 18 | vhighfs |

high velocity fullstep selection |

ph3sel=0, only |

| 17 | vsense |

sense resistor voltage based current scaling |

0: Low sensitivity, high sense resistor voltage 1: High sensitivity, low sense resistor voltage |

| 16 | tbl1 |

TBL blank time select |

%00 to %11: Set comparator blank time to 16, 24, 36 or 54 clocks Hint: %10 is recommended for most applications |

| 0X6C, 0X7C: CHOPCONF – CHOPPER CONFIGURATION 15 to 0 WITH PH3SEL=1 (3 PHASE MOTOR) |

||||

| Bit | Name | Function | Comment | |

| 15 | tbl0 |

(see tbl1 in bit 16) |

||

| 14 | - | reserved |

set to 0 |

|

| 13 | rndtf |

random TOFF time |

0 | Chopper off time is fixed as set by TOFF |

| 1 | Random mode, TOFF is random modulated by dNCLK= -12 to +3 clocks. |

|||

| 12 | csync |

chopper synchronization |

0 | Chopper freely running |

| 1 | Synchronize chopper to full steps 11 | |||

| 11 | - | reserved | set to 0 | |

| 10 | nosd3ph |

0 | Each chopper on-cycle is followed by a slow decay phase as set by TOFF | |

| 1 | Slow decay phases are skipped between the chopper phases, except directly following a short to GND or chopper synchronization. | |||

| 9 | hyst5 | HYST hysteresis value for three phase chopper |

DAC hysteresis setting: %00000 to %11111: 0 to 63 (1/512 of this setting adds to current setting) Attention: Effective HYST/2 must be ≤ 255-sinewave peak (248 at max. current setting) – Reduce current setting to 28 for maximum hysteresis. Do not work with too small setting (poor performance). I_RUN=31 requires HYST < 16 I_RUN=30 requires HYST < 32 I_RUN=29 requires HYST < 48 Hint: Hysteresis decrement is done each 16 clocks |

|

| 8 | hyst4 |

|||

| 7 | hyst3 |

|||

| 6 | hyst2 |

|||

| 5 | hyst1 |

|||

| 4 | hyst0 |

|||

| 3 | toff3 | TOFF off time and driver enable |

Off time setting controls duration of slow decay phase NCLK= 12 + 32*TOFF (Minimum is 64 clocks) %0000: Driver disable, all bridges off %0001: 1 – use only with TBL ≥ 2 %0010 to %1111: 2 to 15 |

|

| 2 | toff2 |

|||

| 1 | toff1 |

|||

| 0 | toff0 |

|||

| 0X6D, 0X7D: COOLCONF – SMART ENERGY CONTROL COOLSTEP AND STALLGUARD2 | ||||

| Bit | Name | Function | Comment | |

| _ | - | reserved | set to 0 | |

| 25 | sspd | stallGuard2 speed (3 phase motor only) |

0 | Standard mode, high time resolution for stallGuard2 |

| 1 | stallGuard2 uses more filtering, use for low motor velocity only. Set this bit, if stallGuard value ripple is too high. | |||

| 24 | sfilt | stallGuard2 filter enable |

0 | Standard mode, high time resolution for stallGuard2 |

| 1 | Filtered mode, stallGuard2 signal updated for each four fullsteps (resp. six fullsteps for 3 phase motor) only to compensate for motor pole tolerances |

|||

| 23 | - | reserved | set to 0 | |

| 22 | stallGuard2 threshold value |

stallGuard2 threshold value |

This signed value controls stallGuard2 level for stall output and sets the optimum measurement range for readout. A lower value gives a higher sensitivity. Zero is the starting value working with most motors. -64 to +63: A higher value makes stallGuard2 less sensitive and requires more torque to indicate a stall. |

|

| 21 | ||||

| 20 | ||||

| 19 | ||||

| 18 | ||||

| 17 | ||||

| 16 | ||||

| 15 | seimin | minimum current for smart current control |

0: 1/2 of current setting (IRUN) 1: 1/4 of current setting (IRUN) |

|

| 14 | sedn1 | current down step speed |

%00: For each 32 stallGuard2 values decrease by one %01: For each 8 stallGuard2 values decrease by one %10: For each 2 stallGuard2 values decrease by one %11: For each stallGuard2 value decrease by one |

|

| 13 | sedn0 |

|||

| 12 | - | reserved | set to 0 | |

| 11 | semax3 |

stallGuard2 hysteresis value for smart current control |

If the stallGuard2 result is equal to or above (SEMIN+SEMAX+1)*32, the motor current becomes decreased to save energy. %0000 to %1111: 0 to 15 |

|

| 10 | semax2 |

|||

| 9 | semax1 |

|||

| 8 | semax0 |

|||

| 7 | - | reserved | set to 0 | |

| 6 | seup1 | current up step width |

Current increment steps per measured stallGuard2 value %00 to %11: 1, 2, 4, 8 |

|

| 5 | seup0 | |||

| 4 | - | reserved | set to 0 | |

| 3 | semin3 | minimum stallGuard2 value for smart current control and smart current enable |

If the stallGuard2 result falls below SEMIN*32, the motor current becomes increased to reduce motor load angle. %0000: smart current control coolStep off %0001 to %1111: 1 to .15 |

|

| 2 | semin2 |

|||

| 1 | semin1 |

|||

| 0 | semin0 |

|||

| 0X6F, 0X7F: DRV_STATUS – STALLGUARD2 VALUE AND DRIVER ERROR FLAGS |

|||

| Bit |

Name |

Function | Comment |

| 31 | stst |

standstill indicator |

This flag indicates motor stand still in each operation mode. It is especially useful for step & dir mode. |

| 30 | olb |

open load indicator phase B | 1: Open load detected on phase A or B or on any phase for a three phase motor. Hint: This is just an informative flag. The driver takes no action upon it. False detection may occur in fast motion and standstill. Check during slow motion, only. |

| 29 | ola |

open load indicator phase A | |

| 28 | s2gb | short to ground indicator phase B |

1: Short to GND detected on phase A or B or on any phase for a three phase motor. The driver becomes disabled. The flags stay active, until the driver is disabled by software or by the ENN input |

| 27 | s2ga |

short to ground indicator phase B |

|

| 26 | otpw |

overtemperature pre-warning flag | 1: Overtemperature pre-warning threshold is exceeded. The overtemperature pre-warning flag is common for both drivers. |

| 25 | ot |

overtemperature flag | 1: Overtemperature limit has been reached. Drivers become disabled until otpw is also cleared due to cooling down of the IC. The overtemperature flag is common for both drivers. |

| 24 | stallGuard | stallGuard2 status | 1: Motor stall detected (SG_RESULT=0) |

| 23 | - | reserved |

Ignore these bits |

| 22 | |||

| 21 | |||

| 20 | CS ACTUAL | actual motor current / smart energy current |

Actual current control scaling, for monitoring smart energy current scaling controlled via settings in register COOLCONF. |

| 19 | |||

| 18 | |||

| 17 | |||

| 16 | |||

| 15 | fsactive |

full step active indicator |

1: Indicates that the driver has switched to fullstep as defined by chopper mode settings and velocity thresholds |

| 14 | - | reserved |

Ignore these bits |

| 13 | |||

| 12 | |||

| 11 | |||

| 10 | |||

| 9 | SG_ RESULT | stallGuard2 result respectively PWM on time for coil A in stand still for motor temperature detection |

Mechanical load measurement: The stallGuard2 result gives a means to measure mechanical motor load. A higher value means lower mechanical load. A value of 0 signals highest load. With optimum SGT setting, this is an indicator for a motor stall. The stall detection compares SG_RESULT to 0 in order to detect a stall. SG_RESULT is used as a base for coolStep operation, by comparing it to a programmable upper and a lower limit. SG_RESULT is not applicable when dcStep is active – stallGuard2 works best with microstep operation. Temperature measurement: In standstill, no stallGuard2 result can be obtained. SG_RESULT shows the chopper on-time for motor coil A instead. If the motor is moved to a determined microstep position at a certain current setting, a comparison of the chopper on-time can help to get a rough estimation of motor temperature. As the motor heats up, its coil resistance rises and the chopper on-time increases. |

| 8 | |||

| 7 | |||

| 6 | |||

| 5 | |||

| 4 | |||

| 3 | |||

| 2 | |||

| 1 | |||

| 0 | |||

spreadCycle 3-Phase Motor Chopper

The spreadCycle chopper scheme for three phase motors (pat.fil.) is a precise and simple to use chopper principle, which automatically determines the optimum fast decay portion for the motor. Anyhow, a number of settings can be made in order to optimally fit the driver to the motor.

Three parameters control the chopper scheme for a three phase motor:

| Parameter |

Description |

Setting |

Comment |

| HYST |

The hysteresis setting is the main control for the chopper and determines the chopper frequency. A higher setting introduces more current ripple and thus reduces frequency. A too low setting will result in the coil current only loosely following the target current and thus reduced microstep performance, especially in the current zero crossing. A too high setting can cause audible chopper noise. In order to use the full hysteresis range, be careful to set motor current to max. 28. |

0 to 63 | Hysteresis for the chopper |

| nosd |

Selection of the TOFF insertion |

0 | Use TOFF setting for ad-ditional slow decay phases |

| 1 | No slow decay phase | ||

| csync |

This bit switches on chopper synchronization. If enabled, the chopper engine becomes reset with each motor fullstep, in order to avoid a beat occurring between full step sequence and chopper clock. |

0 | Chopper runs freely |

| 1 | Synchronization enable |

||

| TOFF |

Sets the slow decay time (off time). This setting also limits the maximum chopper frequency. For most 3-phase motor applications an off time will not be required. In this case, a dummy value needs to be programmed to this register to enable the driver and the nosd flag shall be set. Setting this parameter to zero completely disables all driver transistors and the motor can free-wheel. |

0 | Chopper off |

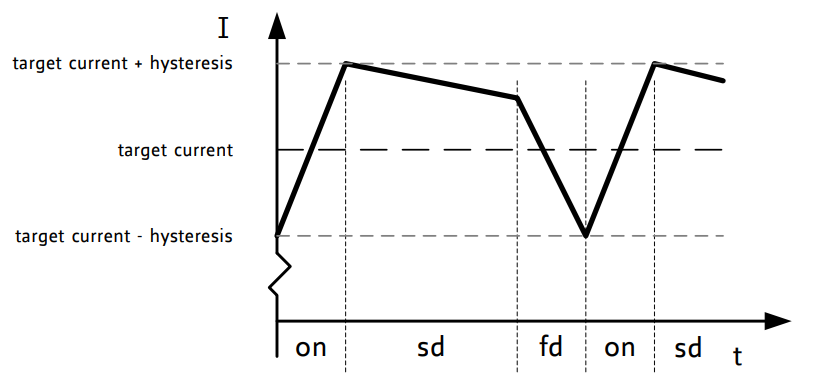

Each chopper cycle is comprised of an on phase, a fast decay phase and a slow decay phase (see Figure 1.2). Optional additional slow decay phases can be added (switch off using nosd bit). The hysteresis determines the chopper frequency by forcing the driver to introduce some amount of current ripple into the motor coils. The motor inductivity determines the ability to follow a changing motor current. The duration of the on- and fast decay phase needs to cover at least the blank time, because the current comparator is disabled during this time.

EXPERIMENTING WITH THE MOTOR

The setting can also be determined by experimenting with the motor: a too low setting will result in reduced microstep accuracy, while a too high setting will lead to more chopper noise and motor power dissipation. The correct setting can be determined best by rotating the motor slowly, and increasing hysteresis setting, until the motion of the motor is very smooth (feel with fingers or add a long pointer to the axis, e.g. laser pointer).

MEASURING MOTOR CURRENTS AT THE SENSE RESISTORS

Alternatively you can measure the motor currents at the sense resistor with a current probe or with an oscilloscope. Check the waves for a pure sine wave. A further increment of the hysteresis setting will lower the chopper frequency and might generate audible chopper noise at some point.