Simple Isolated Telecom Flyback Circuit Provides Regulation Without Optocoupler

Simple Isolated Telecom Flyback Circuit Provides Regulation Without Optocoupler

by

John Shannon

2002-05-01

Introduction

The LT1725 uses a proprietary technique to regulate an isolated output voltage without an optocoupler, thus greatly simplifying flyback converter design and reducing the component count. The result is reduced design time, smaller space requirements, lower cost, and improved performance.

Traditional isolated flyback converters employ a secondary side voltage reference and error amplifier that drive an optocoupler, which sends the control signals back to the primary side. In addition to being parts intensive, this approach places an optocoupler in the feedback loop, which introduces a host of design problems. Optocouplers are poorly defined components—their gain is variable and subject to degradation over time. They are also relatively slow. Optocoupler shortcomings add considerably to the total converter design time and ultimately limit performance.

Consider instead the schematic of Figure 1. This is a flyback converter based on the LT1725. There are extremely few components and yet a high level of functionality. This design is short circuit proof and includes an input undervoltage lockout for increased reliability. The performance of this converter is shown in Figure 2. Output voltage is regulated to within 1% over a 2:1 input voltage range with 10% or greater load. No load regulation is within 2% over a 2:1 input voltage range. This is well within the typical requirement of 5% regulation.

Figure 1. –48V to 5V 2A isolated flyback converter.

Figure 2. LT1725 regulation.

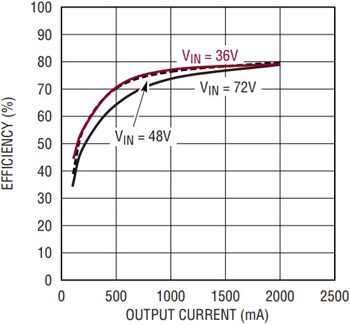

Figure 3. Efficiency vs output current for the circuit in Figure 1.

Circuit Operation

The LT1725 flyback controller is a current mode control IC. Current mode operation provides for inherent line transient rejection and simple loop compensation. Current mode controllers have an “inner” fast current control loop and a slower “outer” voltage control loop. The inner current loop has immediate pulse-by-pulse control of the switching MOSFET M1. A normal switching cycle is as follows. The MOSFET M1 is turned on to begin the cycle. Once M1 is turned on, the current in the primary winding of the flyback transformer ramps up. When the primary current reaches a level determined by the value of the voltage on the VC pin, M1 is turned off. The voltage on the VC pin is set by the LT1725’s output voltage control loop—the outer loop. Once M1 turns off, the current that had been flowing in the primary of the transformer begins to flow in the secondary. The voltage on the drain of M1 rises to a level determined by the transformer turns ratio and the output voltage. Similarly, the voltage on the feedback winding rises to a level set by the output voltage. The LT1725 reads the voltage on the feedback winding during the flyback pulse using a proprietary sampling technique. This sampled voltage is then compared a precision internal reference and current is added to or subtracted from the capacitor on the VC pin. This has the effect of modifying the M1 turn-off current in such a way as to regulate the output voltage. An important benefit of this sampling technique is that output voltage information arrives at the controller about a microsecond after the switching cycle is terminated. In a conventional optocoupler-based design. Delays of tens to hundreds of microseconds occur in the optocoupler alone, severely limiting the converters transient response. Additionally the LT1725 features internal slope compensation. This suppresses sub-harmonic oscillations that can occur with less sophisticated current mode controllers. Sub-harmonic oscillations increase output voltage ripple and increase switching stress.

Conclusion

The LT1725 isolated flyback controller greatly simplifies the design of isolated flyback converters. Compared to traditional opto-isolated designs, an LT1725 based circuit has far fewer components, superior transient response and is easier to stabilize.