Power Consumption: a Primary Consideration in Smart Transmitter Design

Designing loop-powered field instruments with a 4 mA to 20 mA analog output and a HART® (highway addressable remote transducer) interface within the required power budget can be challenging. Modern field instruments, otherwise known as smart transmitters, are intelligent, microprocessor-based devices that monitor process control variables. Such field devices are becoming increasingly intelligent as more and more processing capabilities are being distributed into the field domain. The incorporation of such additional intelligence, as well as increased functionality and diagnostic capabilities heightens the challenge involved in developing a system that can operate effectively within the limited power available from the 4 mA to 20 mA loop. This article explores the power consumption challenge faced by system designers and provides insights into how a sample solution developed by Analog Devices and registered with the HART Communication Foundation tackles this challenge, both at the overall system level and within the fundamental signal chain elements of the smart transmitter design.

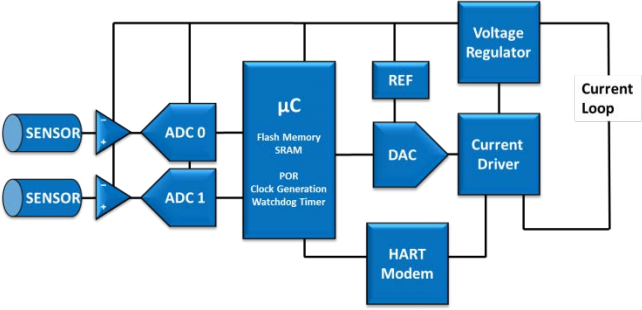

Figure 1. Smart Transmitter Signal Chain.

The most important element of any transmitter is the primary sensor and its optimum operation to deliver the most accurate representation of the environmental parameter being measured. The primary variable is often dependent on a secondary variable (for example, the temperature compensation of a pressure sensor). In the example shown in Figure 2, the sensor is a resistive bridge with 5 kΩ impedance, and the chosen mode of operation is a continuous 3.3 V voltage excitation. This results in the sensor consuming 660 µA of the overall system power budget.

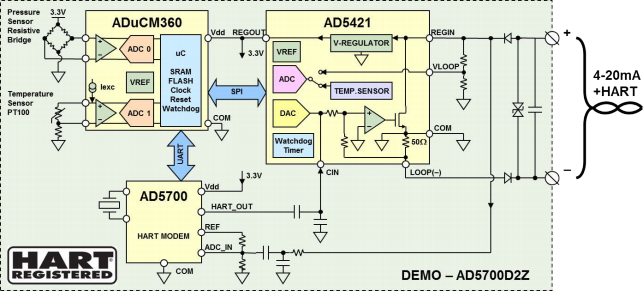

Figure 2. HART Enabled Field Instrument Demo Block Diagram.

The ADuCM360 precision analog microcontroller integrates two low noise precision instrumentation amplifiers with programmable gain. The amplifiers are optimized for the lowest possible power and their stages are switched on only when needed for the required gain. This allows the best trade-off to be made between the circuit’s performance and power requirements. In the sample circuit described here, the primary sensor could be used with only half the excitation voltage, resulting in half the signal level, and optimizing the signal chain performance by programmatically doubling the amplifier gain from 16 to 32. This would mean a saving of 330 µA in sensor excitation current and an increase of 60 µA in the amplifier supply current—giving a net saving of 270 µA. When considering such trade-offs, there are indeed other aspects to consider; for example, the sensor signal-to-noise ratio during external electromagnetic disturbance. The fully integrated programmable solution can help to make evaluation of these options easier for the designer.

Two 24-bit analog-to-digital converters (ADCs) sample the amplified primary and secondary sensor signals and translate them to the digital domain. In Figure 2, the ADCs are integrated on the ADuCM360 and again optimized for the lowest power needed for the required performance. The Σ-Δ architecture offers inherent high resolution, linearity and precision, and the digital filter, which is always included in the Σ-Δ ADC, allows programmable trade-offs between the required signal bandwidth and the input noise, the latter having a direct impact on the achievable resolution. Often a resolution higher than 16 bits is needed on the field instrument input in order to deliver 16-bit resolution on its output.

A microcontroller is used for processing the inputs from all the field instrument sensors and for calculating the resulting value of the measured process variables. On top of that, the processor is required to perform more diagnostics as well as more complex communications. In this example, a 32-bit ARM Cortex®-M3 RISC processor is used, complemented by 128 kB of flash memory, 8 kB of SRAM, and other peripherals such as power-on reset functionality, clock generation, digital interfaces, and a range of diagnostics features. The microcontroller is thus a complex component, with the potential to require a lot of power, so the more processing that can be done per every mW, the better.

An obvious trade-off in the system is between the microcontroller core speed and the supply current. A less obvious power saving can be achieved by choosing the lowest necessary clock frequency for each of the digital peripherals, such as serial interfaces and timers. In this example, the fastest the 4 mA to 20 mA output is updated is every 1 ms. While the ADuCM360 allows the SPI interface to be clocked at a maximum of 16 MHz, using a moderate 100 kHz serial clock with optimum clock subdividers saves around 30 µA on the chip itself. An additional few µA are saved by lowering the dynamic currents related to the parasitic capacitance of the SPI signals on the printed circuit board (PCB) tracks and the component pin capacitances. The Cortex-M3, used on the ADuCM360, consumes around 290 µA/MHz. It includes very flexible internal power management options, with the ability to dynamically switch power and clock speeds to the internal blocks, to allow the optimum system power vs. performance balance.

The field instrument 4 mA to 20 mA output current is set by a digital-to-analog converter (DAC) followed by an output current driver. The AD5421 integrates both the 16-bit DAC and the current output stage. It also incorporates a precision voltage reference and programmable voltage regulation circuitry, necessary to extract the power supply from the loop, to power both itself and the rest of the transmitter signal chain. Furthermore, the AD5421 provides a number of on-chip diagnostic features, all of which can be configured and read by the microcontroller, but can also operate autonomously. Even with such a high level of integration, the AD5421 has a maximum total current of only 300 µA and a total unadjusted error specification over temperature of less than ±0.05% FSR, maximizing the granularity and accuracy of the communicated measurement without adversely affecting system power consumption.

Finally, complementing the 4 mA to 20 mA analog output is a HART modem that plays an essential role in modern control systems, providing digital communication with the host system. The HART communication allows the implementation of features unthinkable with analog-only communication. Examples include the host retrieving the instrument’s secondary variables, diagnostics information or performing remote calibration routines. Again, low power, as well as a small footprint, are important considerations when designing the HART circuit. The AD5700 is used here. With typical transmit and receive currents of 124 µA and 86 µA respectively, the AD5700 will not contribute significantly to the overall instrument current budget. The HART output modulates the output current and is interfaced via a dedicated pin to the internal summing node inside the AD5421. The HART input is coupled from the current loop via a simple passive RC filter. The RC filter works as the first stage band-pass filter for the HART demodulator, and also improves the system electromagnetic immunity, important for robust applications working in harsh industrial environments. The clock for the HART modem is generated by the on-chip low power oscillator with a 3.8664 MHz external crystal with two 8.2 pF capacitors to ground, connected directly to the XTAL pins. This configuration utilizes the least possible power.

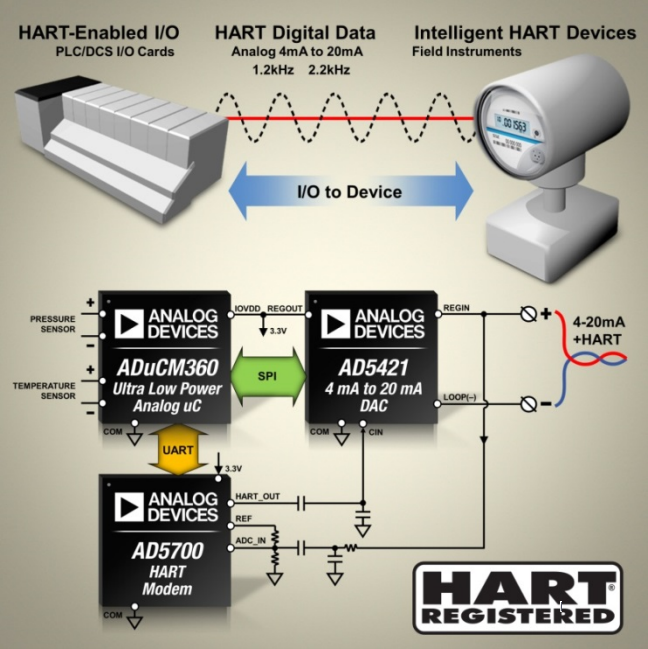

Figure 3. Complete 4 mA to 20 mA Loop-Powered Field Instrument with HART Interface.

Having examined the complete signal chain, it is obvious that in an application such as this, where every microamp counts, the HART enabled field instrument demo circuit shown in Figure 3 proves invaluable. Table 1 outlines the breakdown of current, as measured, in this DEMO-AD5700D2Z system, showing the total current to be well within the 3.5 mA (“low alarm” setting) maximum allowable system power budget available for such a design.

| Circuit Block | Supply Current (mA) | % of Total Current | |

| Sensor |

Primary sensor (resistive bridge, 5 kΩ at 3.3 V) | 0.660 | |

| Secondary sensor (RTD, 200 μA excitation) | 0.200 | ||

| Sensor Total | 0.860 | 28% | |

| ADuCM360 |

Instrumentation amplifier 1 (gain = 8) | 0.130 | |

| Instrumentation amplifier 2 (gain = 16) | 0.130 | ||

| 24-bit ADC 1, including input buffer | 0.140 | ||

| 24-bit ADC 2, including input buffer | 0.140 | ||

| Voltage reference, RTD current source reference | 0.135 | ||

| ADuCM360 Analog Circuitry Total | 0.675 | 22% | |

| Microcontroller core (@ 2 MHz) and memory | 0.790 | ||

| SPI, UART, timers, watchdog, other circuitry | 0.085 | ||

| Clock generator | 0.170 | ||

| ADuCM360 Digital Circuitry Total | 1.045 | 34% | |

| AD5421 |

16-bit DAC | 0.050 | |

| V-to-I driver | 0.060 | ||

| Voltage reference | 0.050 | ||

| Power management, voltage regulators | 0.055 | ||

| SPI, watchdog, other circuitry | 0.010 | ||

| AD5421 Total | 0.225 | 7% | |

| AD5700 |

Modulator/demodulator (worst case, transmitting) | 0.124 | |

| Clock generator (with external crystal) | 0.033 | ||

| AD5700 Total | 0.157 | 5% | |

| Other circuitry on board, dynamic currents | 0.138 | 4% | |

| Combined Total | 3.100 | 100% |

In conclusion, not only does this solution deliver on low power, but it is also a high performance solution, with minimum area overhead, not to mention HART compliance. It has been compliance tested, verified and registered as an approved HART solution with the HART Communication Foundation. This successful registration instills confidence in circuit designers when using the components outlined in the circuit. The high level of integration in the ADuCM360 enables a high level of flexibility, and shifts the focus from traditional discrete component designs to the optimum use of each integrated block within the chip. The system designer can explore the previously described trade-offs, even at late stages of a design, by simply changing the circuit setup in the software. This allows for short design cycles, ease of circuit modifications, and tuning of circuit performance, without the need to go through costly and time consuming PCB revisions. This integrated and fully programmable CN0267 solution is fully documented, with hardware available to order online.

Figure 4. HART Registered Field Instrument Demo Board.