Thought Leadership

Parasight

Trinamic’s Stepper Motor Control Module Helps Combat Malaria

Malaria is the world’s most fatal infectious disease. Common throughout tropical areas of Asia, Africa and South America, treatment for malaria is effective if diagnosed early. The standard malaria test requires visual examination of blood samples under a microscope by a trained technician to confirm the existence, quantity and type of malarial parasites. More than 175 million malaria tests are performed annually in India alone.

Sight Diagnostics, an Israeli start-up, developed a unique diagnostic technology that offers significant improvement over human microscopy for malaria detection. Using patent-pending image processing and advanced algorithms, Sight Diagnostic’s Parasight Platform™ identifies, enumerates and characterizes malaria suspect blood samples faster, and more consistently, than a human technician.

Sight Diagnostics turned to stepper motor specialist Trinamic Motor Control as a key supplier for its Parasight Platform. An autonomous diagnostic system the size of a coffee maker, the Parasight Platform accepts 30 individual blood samples in a loading tray, examining each sample under a digital imaging lens.

The current Parasight Platform design uses four stepper motors:

- Two stepper motors move the sample slide through a predetermined X/Y search grid to complete a thorough assay of the blood sample under test.

- A third stepper motor controls the Z-axis image focus mechanism.

- And a fourth stepper motor manages the feed conveyor for the multisample load tray.

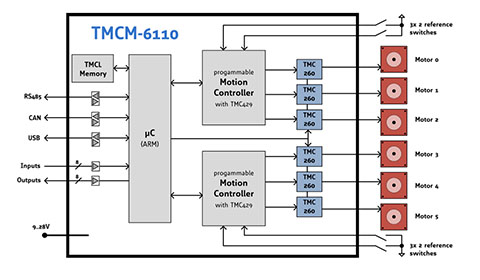

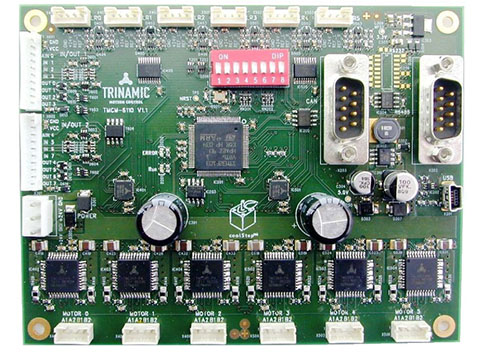

As a start-up with limited resources, Sight Diagnostics selected TRINAMIC’s off the shelf TMCM6110 stepper module for the Parasight Platform. Ideal for systems that use between 3 and 6 motor axes, the compact, low-power TMCM6110 board incorporates TRINAMIC’s TMC429 stepper motor control ICs and TMC260 stepper motor drivers to independently control each axis. These devices are preconfigured to match the performance requirements of NEMA 17 stepper motors. An onboard ARM micro-controller coordinates the activity of each motor, and handles communication with a host processor through an RS-485, CAN or USB interface.

The TMCM-6110 offers precision control with motion granularity of 256 microsteps per full step, which met the requirements of the Parasight Platform. Using TMC’s intuitive and high-level development tools, Sight Diagnostics was able to quickly implement and optimize their motion control applications while keeping their strategic design efforts focused on the enhancement of their unique IP — including advanced imaging technology and algorithms.

The driver module also met Sight Diagnostic’s demanding requirements for reliability, low maintenance and cost effectiveness. The Parasight Platform is designed to work in tropical conditions with ambient temperatures up to 37°C. while being rugged enough for operation in rural locations far from maintenance facilities and service technicians.

“We had two primary goals when we selected a motion control vendor for our Parasight Platform,” explained Sight Diagnostics CEO Yossi Pollak. “With limited time and engineering manpower to devote to this non-core aspect of our product, we required a motion control module that was absolutely intuitive with respect to ease-of-design. And having implemented our motion control algorithm, we required cost competitive components that would be under the strain of constant use under adverse conditions, with the reliability required by medical applications.”

The Parasight Platform is currently undergoing extensive field tests and clinical trials. It has achieved accuracy rates exceeding 99%, at speeds that are 50X faster than highly trained human operators. The company expects successful global deployment of this diagnostic tool in 2015. Sight Diagnostics is currently developing additional diagnostic tools.

詳細を閉じる

詳細を閉じる