要約

In this design solution, we review a typical electric vehicle (EV) battery system, highlighting its complexity in terms of isolation, current sensing, and processing. Subsequently, a low-noise, cost-effective, capacitive-isolation daisy-chain communication IC is introduced that streamlines the junction box, eliminating the need for a dedicated microprocessor. Integrated current sensing using shunt or hall sensors eliminates the need for multiple components and enables smaller footprint. Isolation resistance between the chassis ground and battery module is measured with a simple resistive network and reported to the IC for processing.

Introduction

Electric vehicles (EVs) are powered by huge battery banks (Figure 1), constructed of long strings of batteries in series that can achieve operating voltages higher than 800V and an average current of 40A. Each cell voltage is monitored by control modules and, if necessary, appropriate control methods are applied to keep voltage deltas between cells to a tight tolerance. The junction box controls the high-voltage connections for the charging system, inverter/motor, and battery pack. High-voltage connections, currents, and isolation resistance are measured within this module and sent back to the main ECU for SOC and power calculations, monitoring vehicle status, and ensuring safety during various vehicle conditions.

Figure 1. EV car battery pack and wiring.

In this design solution, we review the structure of a typical EV battery system with the associated junction box. We then introduce a novel junction box design that is streamlined, better integrated into the system. and capable of reporting measurements that are time-aligned with the rest of the system.

Distributed Battery System Architecture

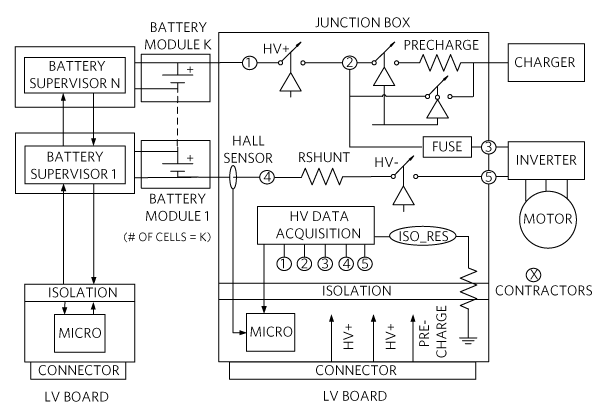

Figure 2 illustrates a typical distributed battery system. As an example, on the left of the battery pack, eight supervisory modules (N=8), residing on the high-voltage board, each control 14 rows (K=14) of cells in series with each row comprised of 70 batteries in parallel (a 7840 Li+ batteries ensemble). Isolation is required between the microprocessor and the first module, and from one module to the next. The data is subsequently passed along to the microcontroller on the low-voltage board.

On the right of the battery pack, the junction box senses six critical voltage nodes (contactors and isolation ISO_RES) and a Hall sensor measures the current. The data is then passed along to a second microprocessor.

Monitoring the contactor voltage nodes is important in order to check the health of the batteries when contactors are closed and when they are open. It is safety-critical since it also tells the system when the contactors are in the correct state.

Figure 2. Typical system architecture of a distributed battery system.

Streamlined System Architecture

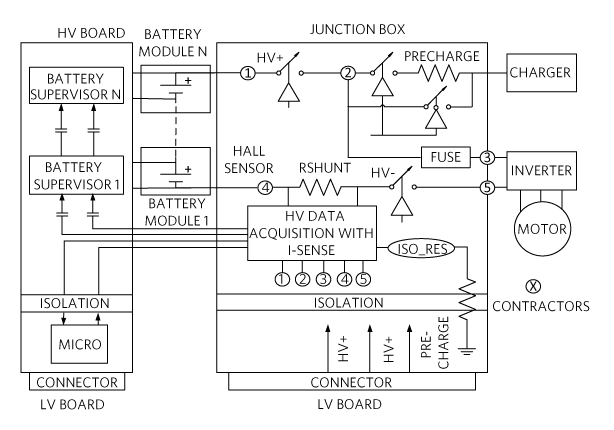

In the streamlined inmplementation in Figure 3, DC-blocking capacitors (or transformers) are used to isolate daisy-chain devices that operate at different common-mode voltages. Inexpensive capacitors can be used in the daisy chain between modules, which reduces system cost. Further, the daisy chain can be easily extended to incorporate the junction box data acquisition IC, which eliminates the need for a local microprocessor and enables time alignment between measurements from the junction box and those from the battery modules. Time alignment is important because it gives better correlation for power management and calculations. Finally, the junction box high-voltage data acquisition IC has current-sensing capability that enables flexibility in using either a shunt resistor (shown here) or Hall effect current sensor, or both (for redundancy).

Figure 3. Streamlined system architecture.

HV Data Acquisition with Current Sense

As an example, the MAX17852 is a flexible data-acquisition system for the management of high-voltage and low-voltage battery modules. The system can measure 14 cell voltage nodes (or seven ground referenced high voltage nodes), one current, and a combination of four temperatures or system voltage measurements with fully redundant measurement engines in 263µs. It can also poll all inputs solely with the fast ADC SAR measurement engine in 156µs.

This highly integrated battery sensor incorporates a high-speed differential UART bus for robust daisy-chained serial communication, designed for maximum noise immunity. Up to 32 devices can be daisy-chained. The single daisy chain enables time-alignment between the junction box and the battery supervisory measurements. Accordingly, cell voltage, bus bar measurements, pack voltage, pack current, contactor voltages, and temperature measurements are aligned within 10µs.

The system uses Analog’s battery-management UART or SPI protocol for robust com¬munications and supports an I2C master interface for external device control. it is optimized to support a reduced feature set of internal diagnostics and rapid-alert communication through both embedded communication and hardware-alert interfaces to support ASIL D and FMEA requirements.

Battery Electrical Isolation Measurement

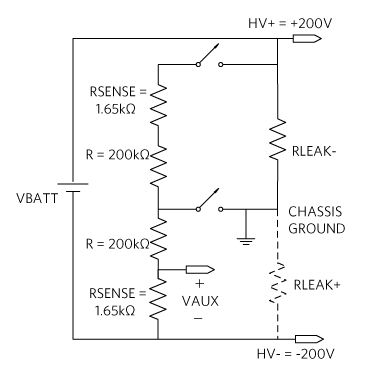

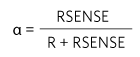

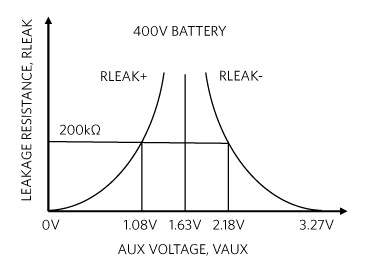

The Department of Transportation (TP-305-01) prescribes for this measurement a resistance (in ohms) approximately 500 times the nominal operating voltage of the vehicle (in volts) per SAE 1766, between the negative (positive) side of the propulsion battery and the vehicle chassis, namely 200kΩ for 400V. Accordingly, the isolation resistance RLEAK- (RLEAK+) between the chassis and the battery positive (negative) can be sensed with the network shown in Figure 4 and reported as a voltage to the AUX pin of the data acquisition IC.

Figure 4. Battery isolation resistance measurement.

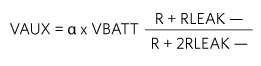

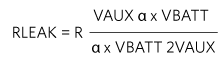

Based on the network in Figure 4, the VAUX equation for the RLEAK- case is:

From which:

Where:

The graph below reports the curves for both RLEAK+ and RLEAK- and shows that the 200kΩ RLEAK- isolation resistance produces a sensed voltage VAUX of 2.18V while a 200kΩ RLEAK+ isolation resistance produces a sensed voltage of 1.08V.

Figure 5. Isolation resistance curve.

Conclusion

Electric vehicles handle high voltages and high currents. Electrical connections contact resistance, currents, and isolation resistance between high-voltage and low-voltage boards must be monitored to ensure safe operation. We reviewed the structure of a typical EV battery and junction box system, highlighting its complexity. Subsequently, we introduced a novel, unique data acquisition IC that, thanks to its low-noise, cost-effective, capacitive-isolation daisy-chain communication architecture that eliminates the need of a junction box-dedicated microprocessor, thanks to its low-noise, cost-effective, capacitive-isolation daisy-chain communication architecture. It also enables time alignment between the junction box and the cell voltage measurement. The integrated current sense eliminates the hall effect current sensor. The fast SAR ADC architecture enables multiple measurement in a minimum amount of time.

A similar version of this design solution originally appeared in Electronic Products on March 31, 2021.