Gate Drive and Current Feedback Signal Isolation in Industrial Motor Drives

Gate Drive and Current Feedback Signal Isolation in Industrial Motor Drives

2015年09月01日

Electric motor energy efficiency has been a focus of energy regulators worldwide for more than two decades. This is part of a global effort to minimize carbon emissions through a combination of increased efficiency in electricity usage and conversion of some energy generation using renewable sources. Early motor efficiency regulations were voluntary, but soon, these became mandatory with minimum efficiency levels increased every five to 10 years. The squirrel cage induction motor (SQIM) has been the workhorse of the industry since the general availability of electricity because it will start and run when connected directly to a 3-phase ac supply. Current IEC standards classify the efficiency of these motors at various levels, according to power rating, that range from standard efficiency (IE1) to super premium efficiency (IE4). Today the IE3 premium efficiency levels are mandatory in the world’s largest industrial regions including the EU, U.S., China, and Japan. Factory operators have not resisted this change because the capital cost of the motor is just a small fraction of the electricity cost during the motor’s lifetime. Even in the case of replacing a premium efficiency motor with a 15 kW super premium efficiency, IE4, motor, the extra cost can be recovered in energy savings within two years. This trend in motor efficiency requirements has been pushing many equipment manufacturers away from direct off-line motors to inverter-based solutions. The various architectures of these solutions, along with their drive and signal isolation requirements are the topics addressed in this article.

SQIM manufacturers have, up to now, seen stricter efficiency regulations as a market opportunity. Premium and super premium efficiency motors cost more in materials, design, and manufacturing than standard efficiency motors but they command a higher market price. However, the development of new IEC efficiency classification levels IE5 and IE6 will cause problems for motor manufacturers. Motor experts believe it will be very difficult and expensive to design line connected SQIMs to meet efficiency levels higher than IE4, especially in the lower power ranges (de Almeida). It is most likely that only inverter connected motors will be capable of meeting the IE5 and higher efficiency levels. Permanent magnet synchronous motors (PMSM) have been traditionally selected for ultrahigh efficiency applications, but the cost and availability of the rare earth rotor magnets is a concern. New axial motor designs using ferrite magnets or new magnetic materials developed to support the growing electric vehicle market may alleviate some of these concerns. Synchronous reluctance motors (SRM) are also being seriously considered for IE5 efficiency level drives (ABB). The SRM has neither rotor windings nor magnets, which supports high efficiency at a lower cost and frame size than an equivalent SQIM with the same power rating.

Inverters and Isolation

This trend toward even more efficient motors is increasing the demand for IGBT-based frequency inverters that transform the rectified mains input into the variable frequency voltages that drive the motor. Inverter controlled motors have the output torque or speed optimally matched to the shaft load to minimize energy consumption, reduce motor running temperatures, and improve motor reliability. Added value control functions such as condition monitoring, power metering, and factory network connectivity enable process efficiency and reliability. Isolation technology is a critical element in the drive system since it safely isolates the controller user interfaces from the dangerous high voltages connected to the inverter.

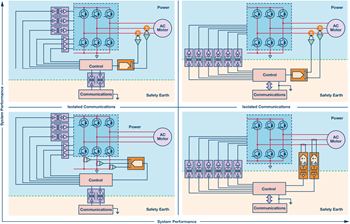

Several high level factors influence the isolation requirements and architecture within a given drive; these include the motor drive performance level, the complexity of the communications interface, the controller architecture, and the voltage levels encountered within the system, as seen in Figure 1.

Figure 1. Consolidated motor control architectures.

In many cases, the key isolation nodes are the gate drivers and the motor phase current sensing circuits. Both locations involve controlled or measured signals that are referenced to switched high voltage levels, and must, at a minimum, include some form of level shifting and in many cases isolation (either functional or safety) in order to apply or extract ground referenced signals.

This is illustrated in the concept schematic of Figure 2, which depicts a single inverter phase leg, in which the level shift and potential signal isolation requirements for the high-side gate driver signal and the phase current shunt measurement signal are indicated.

Figure 2. Signal referencing in a 3-phase inverter leg.

Isolated Gate Drivers

The basic requirements of an isolated gate driver can also be appreciated from Figure 2. These include functional or safety isolation of the logic level switching signal, as well as an output driver capable of driving the IGBT gate voltage past the turn on and turn off thresholds to switch the IGBT at the required time instants minimizing device conduction loss, switching loss, and EMI generation. In 3-phase inverters, the IGBTs are controlled in antiphase, such that both high-side and low-side IGBTs are never on together, even for a short instant. This requires the insertion of a small dead time period between the high-side and low-side switching signals. Minimizing this dead time period is critical in the context of both system performance and IGBT protection (O’Sullivan).

IGBT turn on requires that the IGBT be driven into the saturation region where the conduction losses will be minimized. This typically implies turn on voltages of >12 V. IGBT turn off requires that the IGBT be driven to the cutoff region of operation so that it can successfully block the reverse high voltage across it once the high-side IGBT has turned on. In principle this can be achieved by reducing the IGBT gate emitter voltage to 0 V. However, a secondary effect must be taken into account when the high-side transistor is turning on. The rapid transition of the switch node voltage causes a transient induced current to flow in the low-side IGBT parasitic Miller capacitance (CGD in Figure 3). This current flows through the turn-off impedance of the low-side gate driver (ZDRIVER in Figure 3), creating a transient voltage bounce at the low-side IGBT gate emitter terminals, as shown. If this voltage rises above the IGBT threshold voltage, VTH, it can cause a brief turn on of the low-side IGBT, resulting in a transient shoot through of the inverter leg, increasing power dissipation and compromising reliability.

Figure 3. Miller effect in IGBT switching.

There are generally two approaches to addressing the induced turn on of inverter IGBTs—using bipolar supplies and/or the addition of a Miller clamp. The ability to accept a bipolar power supply on the isolated side of the gate driver provides additional headroom for the induced voltage transient. For instance, a negative supply rail of −7.5 V means that an induced voltage transient of >8.5 V will typically be needed to induce a spurious turn on. This is generally sufficient to prevent a spurious turn on. A complementary approach is to reduce the turn off impedance of the gate driver circuit for a period of time after the turn off transition has been completed. This is known as a Miller clamp circuit. The capacitive current now flows in a lower impedance circuit, consequently reducing the magnitude of the voltage transient. Additional flexibility in the control of switching rates can be provided by utilizing asymmetric gate resistors for turn on and turn off. All of these gate driver functions have a positive impact on overall system reliability and efficiency.

Overcurrent protection in motor drives is generally implemented at several levels. Differentiation between sustained overcurrents and transient overcurrents may be included in the drive protection scheme, and these overcurrent events have differing trip levels and time constants. This type of overcurrent protection is normally implemented based on current measurement. For very rapid and potentially catastrophic overcurrent events, such as short circuits on the inverter outputs, it can be advantageous to have a fast acting protection mechanism integrated within the gate driver. Desaturation protection is realized by monitoring the IGBT collector emitter voltage while the IGBT is turned on. While the IGBT is saturated the on state voltage is a function of the current level within the IGBT, and this protection function can be designed to trigger a fault and rapidly turn off the IGBT once the on-state voltage increases beyond an acceptable level. There is a short blanking time during which the protection circuit does not monitor the on-state voltage of the IGBT. This is included to prevent false triggering at turn on as a result of the collector emitter voltage transition and/or transient overcurrent during the turn-on event.

The ADUM4135 isolated gate driver from Analog Devices incorporates bipolar supply capability, Miller clamp, and asymmetric turn-on and turn-off outputs. In addition, propagation delays and more importantly, propagation delay skew are at industry-leading typical values of 50 ns and 15 ns, respectively. The system impact of reduced dead time is illustrated in Figure 4 where an inverter output line to line voltage at low motor speed is depicted for two different dead time levels. The increased dead time requirement associated with optocoupler technology results in increased motor voltage and current distortion. This reduces performance in terms of increased torque ripple and vibration, as well as reduced efficiency due to increased harmonic losses. These distortion effects are particularly evident in inverter applications, in which control loops are relatively low performance, however, even in high performance drives with high bandwidth current and velocity control, dead time related distortion can be a limiting factor in very low speed performance.

Figure 4. Measured line to line motor voltage at (a) 500 ns dead time (b) 1μs dead time.

Isolated Current Sense

Motor phase current sense nodes are connected to the same circuit node as the gate driver output, as illustrated in Figure 2 for a shunt-based measurement. Therefore, they experience the same isolation voltages and switching transients. Phase current sensing is critical to high performance closed-loop motor control, and realizing a high fidelity measurement in this harsh, electrically noisy environment is not trivial. In higher power systems, isolated current sensors such as current transformers or Hall effect sensors are used in which the isolation is inherent, while in lower power systems the trend is to use shunt resistors with isolated Σ-Δ modulators such as the AD7403 from Analog Devices. The former systems generally use the desaturation gate driver function to implement short-circuit over current protection as outlined, while the latter isolated modulator-based, current sense schemes may implement this directly via a fast, coarse digital filter (O’Byrne). This requires precision timing both for the isolated modulator response and low propagation delays in the gate driver, which Analog Devices iCoupler® technology enables, while traditional optocoupler-based solutions tend to suffer from longer propagation delays.

Regulatory Environment

Once a drive architecture has been developed to meet the required performance, the system must be designed to adhere to industry electrical safety standards. It is critical to understand the isolation requirements presented at the gate driver and current sense nodes in order to choose the appropriate isolation components. Each node can be safety separation (reinforced), basic insulation, or functional insulation. The requirement at any single node may be safety insulation to protect against human shock, or isolation to protect low voltage circuits, or isolation for data integrity and noise mitigation purposes, as depicted in Figure 1. The system-level requirement may be achieved by having multiple insulation barriers. IEC61800-5-1 is a longstanding system-level motor drive standard to which the drive design must adhere for system insulation.

Whatever the standard, it does not address the assessment of components. IEC61800-5-1 suggests that component-level standards that support the system’s standard requirements can be used. IEC60747-5-5 addresses optocoupler-based components, while VDE-0884-10, a nonoptoisolator version of IEC60747-5-5, has addressed digital isolators since 2006. VDE-0884-11 has since been developed and approved in 2014 with additional lifetime characterization requirements. This has been submitted to IEC as IEC60747-17 for approval, which generally has a three year cycle. In the intervening period VDE-0884-11 is available as an IEC equivalent standard, as illustrated in Figure 5.

Figure 5. Evolution of nonoptoisolator standards.

Conclusion

New international regulations on motor energy efficiency are accelerating the migration from fixed speed, direct online induction motors to inverter controlled machines. A common requirement is an IGBT gate drive and some form of current measurement at a minimum for protection in simple open-loop inverters, through to high fidelity current control in drives and servos. The technology requirements of these circuits are increasingly focused on precision both in timing and measurement, as well as reliability and robustness. Signal isolation presents a key challenge both in implementation and addressing system design within the regulatory framework.

著者について

Dara O'Sullivanは、アナログ・デバイセズのソフトウェア・システム・ディレクタです。産業用エッジ/モーション/ロボット・ビジネス・ユニットに所属。産業用モーション制御の分野を対象とした電力変換、制御、監視が専門です。2001年より、研究、コンサルティング、業界における様々な役職といった側面から産業用のアプリケーションや再生可能エネルギーのアプリケーションに取り組んできました。アイルランドのユニバーシティ・カレッジ・コークで工学分...

Nicola O’Byrne is a strategic marketing manager with the Autonomous Mobility Team within the Automotive Business Unit at Analog Devices. Nicola holds a B.Eng. in electrical engineering and microelectronics from University ...