Designing Power Supply Parameters in Five Simple Steps with the LTpowerCAD Design Tool

Designing Power Supply Parameters in Five Simple Steps with the LTpowerCAD Design Tool

著者

Henry Zhang

2015年12月02日

Application Note 158: Introduction

System boards today have an increasing number of power rails and supplies. Since solution size, efficiency, thermal and transient performance are all critical for advanced power solutions, it is more efficient and cost effective to design customized onboard power solutions for a specific application, rather than use commercial power supply bricks. To system engineers, designing and optimizing switching mode power supplies is becoming a more common and necessary task. Unfortunately, this task is often time consuming and technically challenging.

To simplify the design task and improve design quality and productivity, the LTpowerCAD™ program has been developed by power application experts at Analog Devices as a power supply design and optimization tool. This PC-based program is available for free download at www.linear.com/LTpowercad. This article explains how to do a “paper design” of switching mode power supply key parameters in a few simple steps with good results.

“Paper Design” Can Be Difficult and Time Consuming

To design and optimize an onboard power supply, the conventional “paper-design” approach can be difficult and time consuming. After the supply specification is defined, the engineer first needs to select a converter topology, such as a buck converter for voltage step-down or boost converter for voltage step-up applications. Next, the engineer needs to select a power management IC, either based on past experience or web-search tools. After that, the engineer needs to calculate power component values based on his/ her own knowledge or the vendor’s data sheet equations. Then comes the choice of power components, such as inductor capacitors and MOSFETs, from thousands of parts. The next step is to estimate the supply efficiency and power loss, while ensuring component thermal stress to be acceptable. That’s not the end of the story—loop compensation design is another challenging task, since it requires complicated circuit modeling and parameter values beyond the IC data sheet. Finally, the schematic is drawn and the prototype PCB board is sent out for fabrication. Now it’s time for the engineer to power up the board to ensure there’s not an oscillated output or overheating. This design process is a challenging one for an inexperienced power supply designer. Even for experienced power designers, the conventional “paper design” approach and trial and error method are time consuming and difficult, and also inaccurate, lacking optimum results. It can take hours, days or even longer.

LTpowerCAD Design Tool Simplifies the Task

To save the user time and effort and to achieve a high quality design solution, the LTpowerCAD design tool has been developed by the power application experts at Analog Devices. This design tool provides a systematic and simple way to enable the design of the key parameters of a power supply in five simple steps: (1) entering supply specifications and selecting a solution; (2) optimizing power stage components with the help of automatic warnings; (3) optimizing supply efficiency and power losses; (4) designing loop compensation and optimizing load transients; (5) generating a summary report with BOM and PCB size estimation. Figure 1 shows the design flow using the LTpowerCAD design tool.

There are many existing design examples, including Analog Devices demo boards and data sheet circuits in the LTpowerCAD solution library. Users can also save their designs using this tool to build their own solution library. Engineers can leverage such solutions and use them as a quick starting point for future power supply designs. Furthermore, an LTpowerCAD design can be exported as an LTspice® simulation circuit to check time domain supply waveforms and transient performances.

Using these powerful tools, a system engineer can complete a high quality supply circuit design in minutes, instead of hours of days, with good results. The time to first prototype is greatly reduced.

LTpowerCAD Design Steps and Examples

Let’s look into the detailed design steps with an LTpowerCAD design example. For instance, an engineer needs to design an onboard supply with the input of 10.8V to 13.2V (12V ±10%) and output of 1.0V with up to 20A current. This is a typical synchronous buck step-down converter.

Step #1 – Search for a Power Product Solution

The first step is to search for a key power IC or micromodule around which to build a solution. The choice of IC or micro-module can come from past experience, or from the LTpowerCAD solution search page. As shown in Figure 2, on the LTpowerCAD search page, the user can enter the supply specifications and select optional features, then click the “search” soft-key. After that, select the desired part from the list provided by the program.

In Figure 2, at the very left of the IC solution list provided by the program, there are red “LT” symbols or green “Excel” symbols. The red LT symbol means that an LTpowerCAD design tool is available for the part. The green “Excel” symbol means a Microsoft Excel spreadsheet-based design tool is available. If both symbols are in grey color, it means a design tool is not yet available for the part.

In this example, the LTC3833 current mode buck controller is selected for this 12VIN to 1V/20A output supply. Its design tool can be opened by clicking the red “LT” symbol.

Step #2 – Power Stage Design

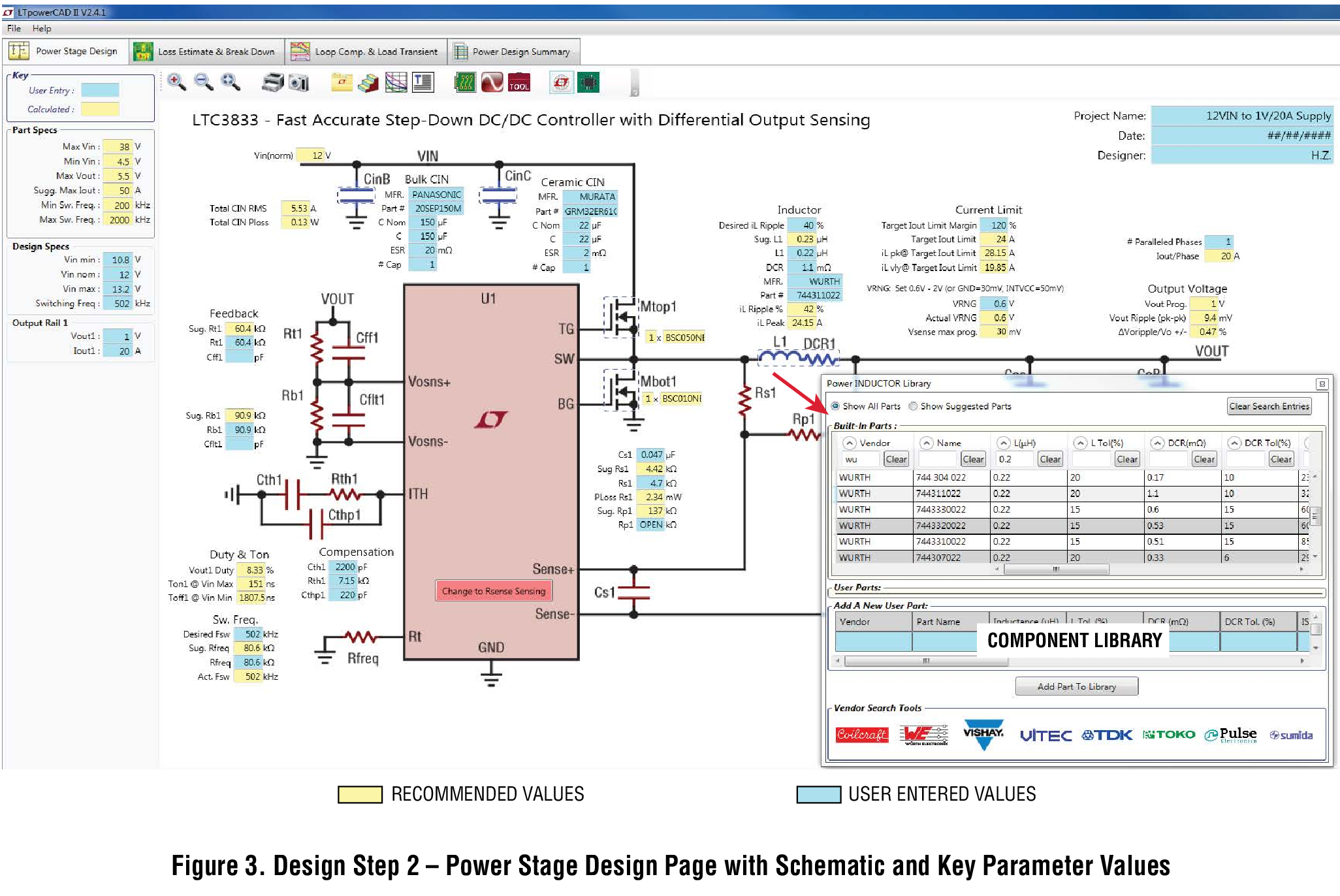

The second step is to design and select power stage components, such as power inductor, input and output capacitors, current sensing components, and power MOSFETs. To design a power supply, the user usually needs to start with a switching frequency, fSW, then select power inductor and, after that, select input and output capacitors. The power MOSFETs can be selected/optimized in Step 3.

Once a design tool is opened, as shown in Figure 3, the main schematic page is shown with design parameter values next to key components. On this page, the design values are in the cells (text boxes) with two different background colors. The yellow color indicates that the value in the cell is either from design specifications, or is calculated/ recommended by the LTpowerCAD tool. The user cannot edit these values directly. The blue color indicates that the value in the cell is the user’s design choice. The user can access and edit these values directly.

For key circuit parameters, such as inductor ripple current, the program has built-in limits for each part. As shown in Figure 4, if a user’s designed value violates the limit, the program provides an automatic warning, showing either an orange cell color as a weaker “soft” warning, or a red cell color as a stronger “hard” warning, to remind and guide the user to check the value and adjust the design. The values of the built-in limits/warnings are recommendations set by the application expert for the related product. It is necessary to note that since it is an analog solution, sometimes it is acceptable to have a design with warnings, so long as the user understands them and is confident with the selected design values.

On this LTpowerCAD schematic page, all the power components, such as inductors, capacitors and FETs, can be selected from the built-in library with a mouse click. As of this writing, there are over five thousand components from many popular vendors, with more components being added frequently. Users can also enter the key parameters of a new component to build their own component libraries on local PCs.

In this example of the 12VIN to 1V/20A buck supply, the switching frequency is set at 500kHz. Therefore, a 0.23μH inductor value is calculated to get 40% peak-to-peak inductor current ripple over DC IO(max). A 0.22μH/1.1mΩ inductor is selected from the inductor library. In this example, the inductor winding DC resistance (DCR) is used for current sensing. The current sensing network values should be checked for a proper current sensing signal and current limit setting. The program shows warnings if the AC current sensing signal is too weak which may cause a potential signal-to-noise ratio issue, or, if the current limit level is lower than the target value. The input capacitors should be selected to meet the RMS current rating with minimum conduction loss. The output capacitors are selected to minimize output voltage ripple and transient overshoot/undershoot. They will be finalized later in the loop compensation and load transient design stage. The power MOSFETs will be selected in the next step for efficiency and loss estimation and optimization.

Step #3 – Supply Efficiency and Loss Optimization

Users can move to the next step to optimize the supply efficiency and power loss by clicking the “Loss Estimation and Breakdown” tab. As shown in Figure 5, after the user selects the MOSFETs and clicks the “update” soft key, the supply efficiency and power loss vs. load current plots are provided for a given input voltage, which can be changed with the VIN sliding bar. The detailed power loss breakdown pie chart further provides users the capability to understand and adjust the design parameters and components to minimize certain losses and optimize overall efficiency.

The LTpowerCAD loss estimation is based on many component models and equations. It includes the losses from power MOSFETs, inductor, capacitors and IC gate drivers. However, to achieve real time results, the device loss models are simplified behavior models instead of complicated physical models. Note that inductor AC losses are not yet modeled in LTpowerCAD, but users have the option to enter its value. As a result, the estimated efficiency can be several percentage points higher than actual hardware efficiency. Even so, this tool provides a fast real-time estimation to help users select and compare various design choices, especially for the inductor and power MOSFETs.

Step #4 – Feedback Loop Design and Transient Optimization

The next step is to design the voltage feedback loop and optimize the load transient performance with good stability margin. This is often viewed as one of the most challenging power supply design tasks. The LTpowerCAD design tool makes it straightforward and easy.

Figure 6 shows the loop and transient design page. The loop gain bode plot can be adjusted in real time to achieve the desired loop bandwidth and phase margin by adjusting the compensation R/C values. The detailed loop design concepts are explained in Reference [2]. For a switching mode power converter, it is usually recommended to have more than 45 degrees or even 60 degree phase margin at the cross-over frequency, and have at least 8dB gain attenuation at the half of supply switching frequency, fSW. There are multiple tabs, including one for a supply output impedance plot to provide users more loop design details. The load transient plot is provided for a user-defined load step size and current slew rate. The user can “freeze plots” for a given design, and then alter design values or component selections to compare with an alternative design for optimum results.

For given load transient conditions (load current step size and slew rate) and VOUT overshoot/undershoot target limit, the user can adjust the loop and check the loop bandwidth, stability and transient performance. If the transient performance still does not meet the target, the user can increase output capacitors (including bulk and ceramic capacitors) and then readjust the loop until the design target is met. Since the LTpowerCAD load transient plots are derived from small signal models, they are very fast, but are only a first order approximation. As a result, it is necessary to leave sufficient (20% to 30%) transient design margins.

To guarantee loop design accuracy, every LTpowerCAD design tool has been bench verified on Analog Devices standard demo boards with loop measurement by Linear engineers before the tool is released. However, in a user’s design, the result can be impacted by component parasitic value variations, such as inaccurate capacitor ESR value. So it is necessary for users to verify their final designs with prototype testing.

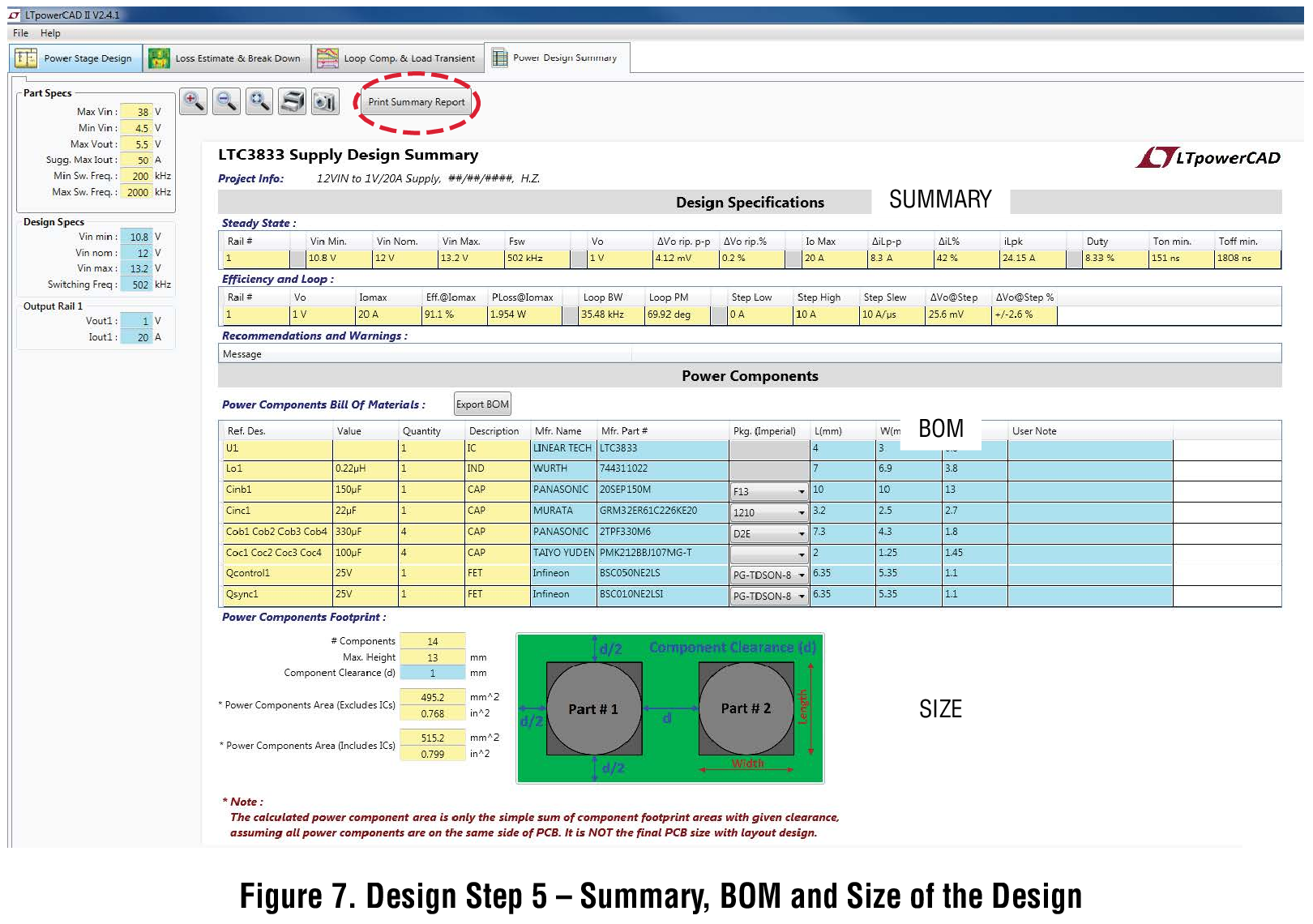

Step #5 – Summary with BOM and Size

As the final step, users can enter the summary page, which provides the design performance summary, as well as a brief bill of materials (BOM) list of power components and a rough estimate of total component footprint size. A summary report can also be printed.

(Optional) Step #6 – Export to LTspice Simulation

There is an optional step to export the LTpowerCAD design to an LTspice simulation file for a real-time simulation to check detailed supply steady state and transient waveforms and performance. This can be done by clicking the LTspice soft key on the LTpowerCAD schematic page to export key design parameters in LTpowerCAD to an LTspice simulation circuit.

Design Solution Library

The LTpowerCAD Design Solution Library is an important feature to help users arrive at a final design quickly with good results. As shown in Figure 9, on the main schematic page, by clicking the “Solution Library” soft key, users can find many existing designs for a given Analog Devices product. These designs can be Analog Devices standard demo boards, data sheet circuits and reference designs. Many of them have been tested and verified in the lab, enabling users to start a new design from one of the existing proved examples. Furthermore, users can save their designs and build a user solution library for future use.

“Sync Release” Ofers Updat es with High Security

The LTpowerCAD II design tool is a Microsoft Windows PC-based program. Users can download the program and install it on a local PC. Compared to a web-based design tool, LTpowerCAD can leverage the full capability and resources of a powerful local PC, without being limited by shared internet and computer resources or data security concerns. After installation, users do not require an Internet connection to run the program. However, users can regularly click the “SYNC RELEASE” key on the program start page to check program updates, such as new tools and features, without requiring a new LTpowerCAD installation.

Summary

The LTpowerCAD design tool provides a powerful, easyto- use method for designing the key parameters of a new power supply in five simple steps. Its standard and user solution libraries enable designers to leverage many existing designs. The design result can be easily exported for LTspice simulation for a detailed performance evaluation. There are also many detailed features not mentioned in this article.[3] In summary, the LTpowerCAD design tool helps system engineers quickly design a new solution with good results and minimum effort and time.