Disposable Metal Boxes Make Excellent Shielded Enclosures

要約

Disposable metal candy boxes, such as those from Altoids, make excellent shielded enclosures for lab tests.

Engineers put extensive effort into designing and constructing lab test circuits which often are left in a drawer, undocumented and vulnerable to damage. The next time the same function is required, either the same engineer or a new engineer builds a new circuit rather than find and analyze the previously built board.

One way to break this wasteful cycle is use the small steel tins in which candies are sold. These boxes, usually about 4" wide, 2.5" deep and 0.5" tall, can easily contain many of the test fixtures. The lids are hinged, allowing easy access to the internal circuits while protecting the same circuits during storage. The steel construction provides both electrical and magnetic shielding.

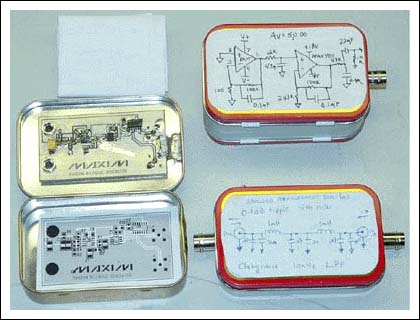

Figure 1. Disposable candy containers make excellent test fixture enclosures.

Figure 1 shows three fixtures constructed using these containers. In the upper right corner is an op amp noise test circuit. The device under test (DUT) and the second stage amplifier have separate power supplies from banana jacks on the top side of the fixture (not shown). The signal is output via a BNC soldered into a hole in the side of the box.

The fixture in the lower right of Figure 1 is a passive LC ladder filter. In this case the circuit is simple enough that the entire schematic is drawn on a label and attached to the top of the candy box. The third fixture, on the left in Figure 1, actually has a plot of the PCB layout glued inside the enclosure. Also, notice the folded paper just above the open lid. This is the actual schematic for the fixture, stored inside the test fixture for future posterity.

Working with these steel enclosures is relatively easy. Be careful when drilling holes, as a drill bit is likely to seize the box out of your hands as the bit emerges through the metal. After drilling, make sure to debur the holes, as the thin steel leaves sharp edges.

Instead of drilling, a reader suggested a handheld punch kit. Available from tool supply houses, punches offer a safer way to make holes in sheet metal.

The boxes can be soldered after sanding the surface to remove paint or other finish coats.

The finished fixtures are easily stacked in a cabinet and will remain useful for future projects. An added benefit is that an otherwise discarded package is recycled. Besides, the mints may improve an engineer's social life.