AN-138: Wireless Power User Guide

Overview

An inductive wireless power system consists of a transmitter that generates a high frequency alternating magnetic field and a receiver that collects power from that field. The resonant coupled system described here provides for increased power transmit distance and reduced alignment sensitivity, with no need for a coupling core.

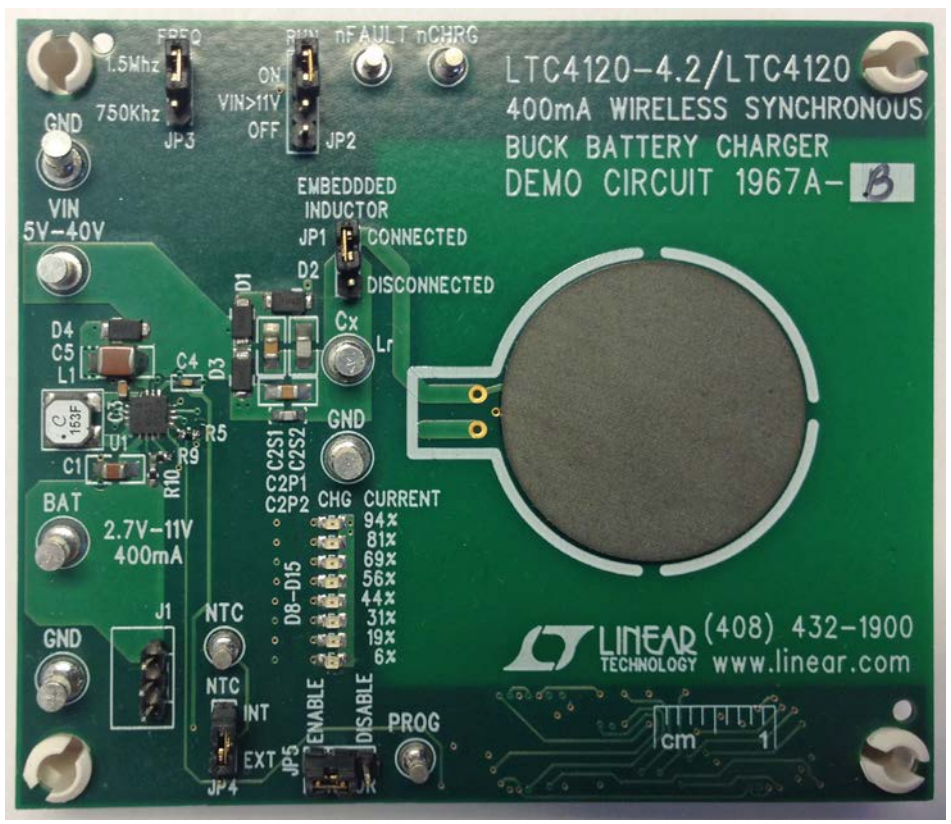

To build a wireless power system four items are required: transmitter electronics, transmit coil, receive coil and receiver electronics. The LTC4120 wireless synchronous buck charger combined with minimal external circuitry comprises the receiver electronics (Figure 1). Please see the LTC4120 product page for more details including the data sheet and demo board design files.

Figure 1. LTC4120 Receiver Demo Board (Rx Portion of DC1969A Kit).

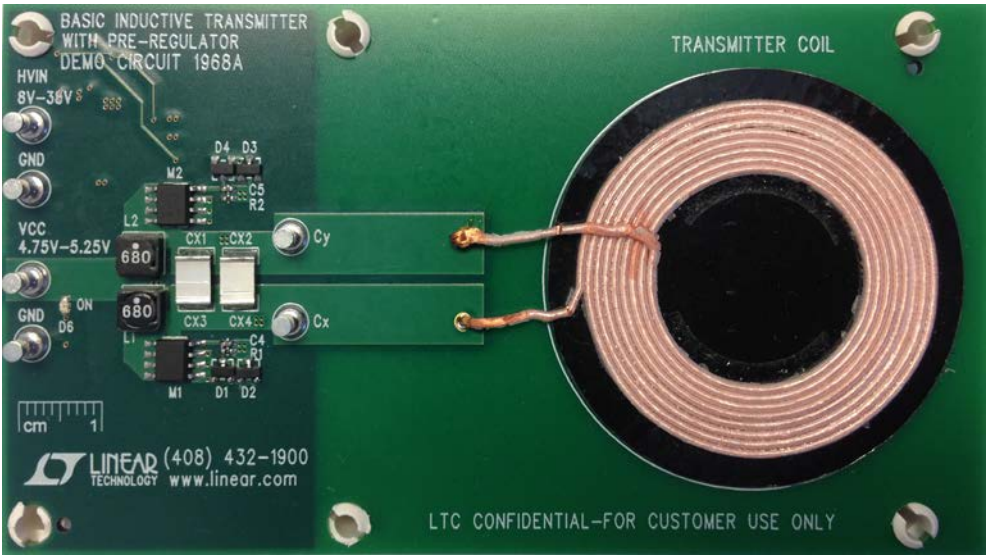

Figure 2. Implementation of Basic Transmitter Reference Design (Tx Portion of DC1969A Kit).

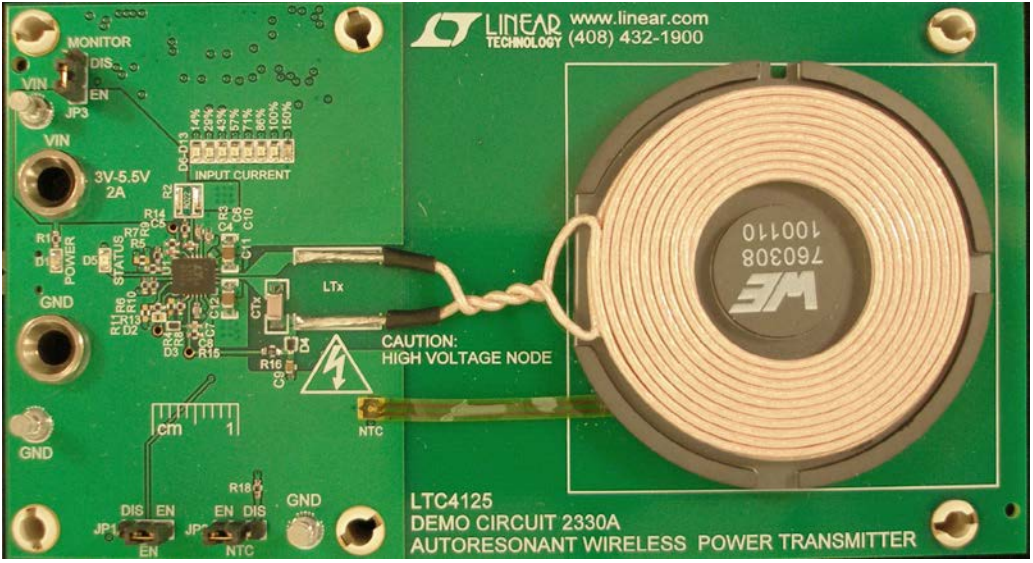

Figure 3. LTC4125 Wireless Power Transmitter Reference Design (DC2330A).

Transmitter Solutions

Currently there are two transmitter options available for design:

- Basic: This wireless power design (Figure 2) was developed by collaboration between PowerbyProxi Inc. and Analog Devices. It is provided as an open source reference design that can be used to integrate the LTC4120 into a wireless power system. The details of the push-pull current-fed resonant converter are described later in this document.

- The LTC4125 AutoResonant Wireless Power Transmitter: A simple monolithic full bridge resonant driver capable of delivering over 5W of power wirelessly to a properly tuned receiver. Unlike the basic transmitter, it offers features such as foreign metal detection, automatic adjustment of transmit power based on the receiver load and temperature fault detection.

Basic Transmitter

The basic transmitter for the LTC4120, described in the following sections, combined with a receive coil and LTC4120-based receiver electronics can be used to produce a wireless battery charging system. This wireless battery charging system enables evaluation of the LTC4120 using standard components.

Basic is a resonant DC-AC transmitter. It is a simple, easy and inexpensive transmitter designed to work with the LTC4120. Pre-regulation is required to provide a relatively precise DC input voltage to meet a given set of receive power requirements. The basic transmitter does not feature foreign object metal detection and can therefore cause these objects to heat up. Furthermore, the operating frequency of the basic transmitter can vary with component selection and load.

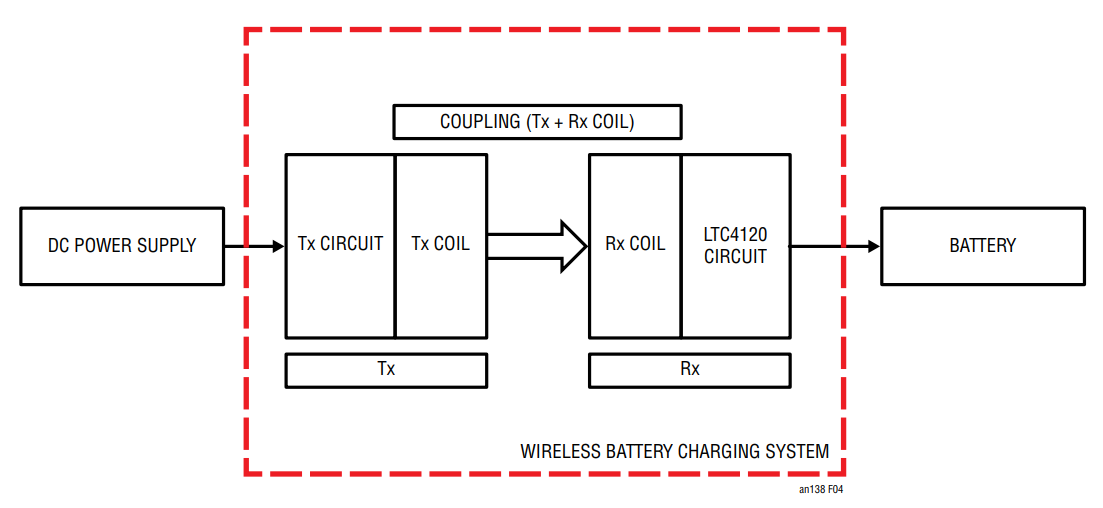

The system draws power from a DC power supply to wirelessly charge multi-chemistry batteries. A block diagram of the system is shown in Figure 4.

Figure 4. Functional Block Diagram of Wireless Battery Charging System.

While the basic transmitter can be used to build a wireless battery charging system, the LTC4125 transmitter is recommended for applications requiring enhanced features as described in Table 5.

System Functional Block Description

LTC4120-based wireless battery charging systems use wireless power transfer technology with Dynamic Harmonization Control (DHC), a patented technique that enables optimal wireless power transfer across a variety of conditions while providing thermal management and overvoltage protection. The resonant coupled system described here eliminates both the need for precise mechanical alignment as well as the need for a coupling core. The charging system is composed of transmitter electronics, transmit coil, receive coil and receiver electronics.

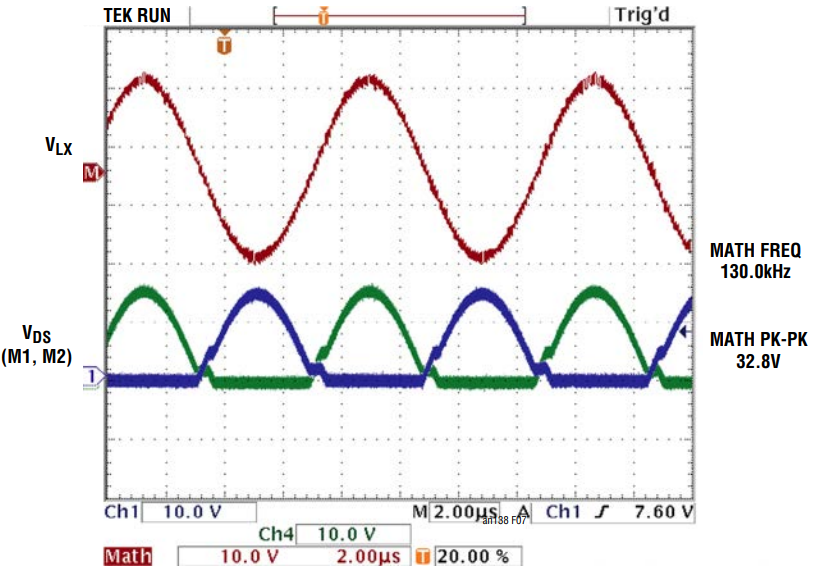

The transmit coil, LX, is energized by the transmitter electronics to generate a high frequency magnetic field (typically around 130kHz, though the operating frequency varies depending on the load at the receiver and the coupling to the receive coil). This magnetic field induces a voltage in the power receive coil, LR. After being tuned with a capacitor, this induced voltage is managed by the LTC4120 in order to control the power transfer. A typical transmitter generates an AC coil current of about 2.5A RMS.

The receive coil, LR, is configured in a resonant circuit followed by a rectifier and the LTC4120. Please see the LTC4120 product page for more details including the data sheet and demo board design files. The receive coil presents a load reflected back to the transmitter through the mutual inductance between LR and LX. The reflected impedance of the receiver may influence the operating frequency of the transmitter. Likewise, the power output by the transmitter depends on the load at the receiver. The charging system, consisting of both the transmitter and LTC4120 charger, provides an efficient method for wireless battery charging. The power output by the transmitter varies automatically based on the power used to charge a battery.

Circuit Description

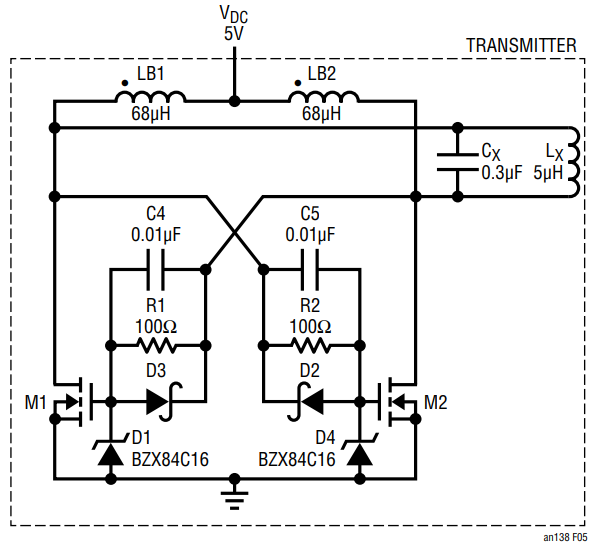

The basic transmitter is a current-fed push-pull transmitter capable of delivering 2W to the battery output of the LTC4120. The basic transmitter schematic is shown in Figure 5. The switches in this push-pull transmitter are driven from the voltage on the opposing leg and no additional control circuitry is required to drive them. The switch driving circuitry consists of a resistor, turn-off diode, gate capacitor and a Zener diode for each switch.

Figure 5. Schematic of a Basic Transmitter for LTC4120.

The voltage rating of the Zener diodes D1 and D4 is chosen to fully turn on M1 and M2 while protecting them from overvoltage.

The current limiting gate resistors R1 and R2 are selected according to the maximum VDS of M1, M2 and the current rating of the Zener diodes.

The resultant voltage waveforms across LX are shown in Figure 6.

Figure 6. System Waveforms (with Receiver and 1.7W Load). Drain Voltage of M1 (CH1), Drain Voltage of M2 (CH4), and Output AC Voltage Across LX.

The basic transmitter design is simple, easy to assemble and test. Table 1 lists components used to build the basic transmitter. The resonant operating frequency of the transmitter should match that of the receiver. The operating frequency is calculated as follows:

| Circuit Code |

Description | Value (Parameters) | Vendor | Vendor Part Number |

| LX | Tx Coil | 5µH | TDK | WT-505060-8K2-LT |

| CX | CX Capacitors | 2 × 0.15µF | Panasonic | ECHU1H154GX9 |

| LB1, LB2 | Inductors | 68µH | TDK | VLCF5028T-680MR40-2 |

| M1, M2 | MOSFET | VDS = 60V, RDS(ON) = 11mΩ | Vishay | Si4108-TI-GE3 |

| D1, D4 | Zener Diode | VZ =16V, PD = 350mW | Diodes | BZX84C16 |

| D2, D3 | Schottky Diode | 40V, 1A | On Semi | NSR10F40NXT5G |

| C4, C5 | Gate Capacitor | 0.01µF, 50V | Kemet | C0402C103K5RACTU |

| LR | Rx Coil | 47µH | Embedded PCB Coil | Link to DC1967A Files |

| Rx Coil Ferrite | 25mm Diameter | TDK | B67410-A223-X195 |

Basic Design Recommendations

Due to the high frequency magnetic fields generated by the transmitter electronics, there is a potential for the induction of eddy currents in foreign metal objects that are within range of the transmitter coil’s field. These eddy currents can result in heat or small induced voltages in these objects. In order to ensure users and devices are not exposed to such hazards it is recommended that:

- A thermal detection system be integrated with the basic transmitter. This detection system should turn the magnetic field off if elevated temperature is detected.

- Electronic devices that are intended to be used with the basic transmitter be thoroughly tested to ensure there is no damage to the device or hazard to the user.

- All practical measures (e.g., labeling and user instruction) be taken to ensure electronic devices not intended for usage with the basic transmitter are not placed on the LX coil.

Measured Data

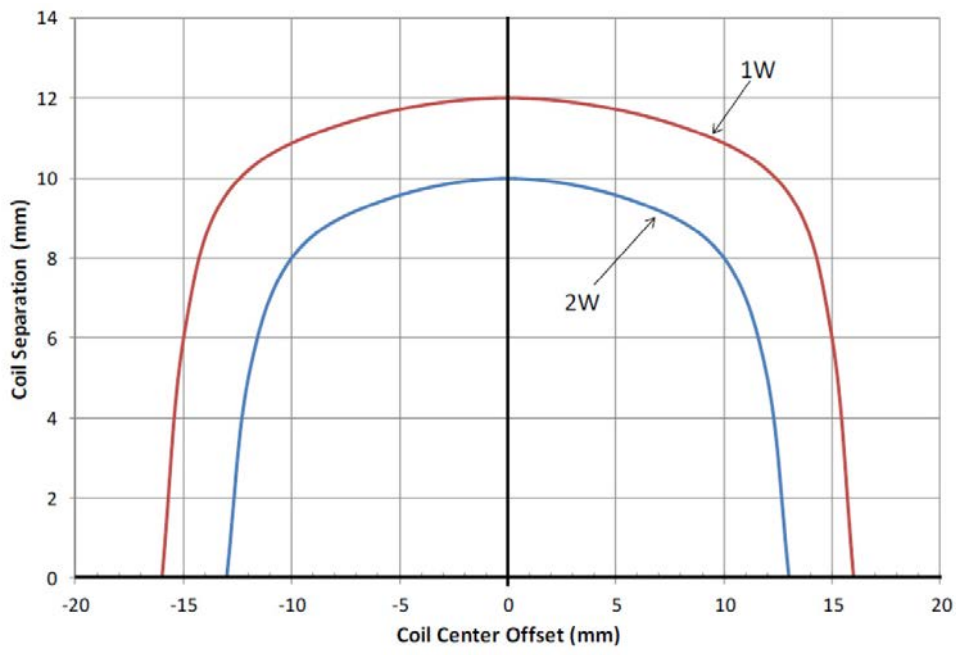

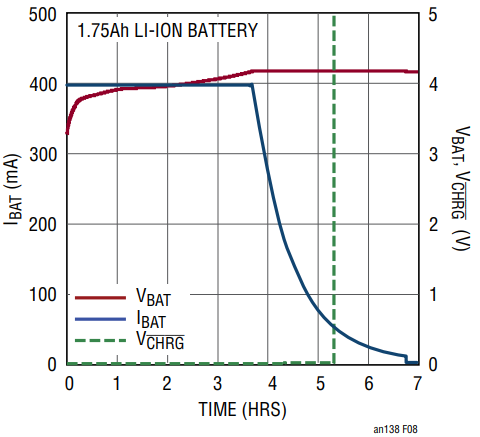

Tables 2 to 4 list circuit parameters that can be verified during testing of the basic transmitter. The testing reflected here was done using the components shown in Table 1. Testing was conducted with Tx and Rx coils with gaps of 4.5mm, 7.5mm and 10.5mm. Figure 7 shows battery charger power curves with respect to transmit and receive coil separation and coil center-to-center offset. Figure 8 shows a typical charge profile with this wireless power configuration. Actual data will vary with component tolerance and specific setup. Demo Board design files and documentation can be found here: https://www.analog.com/en/products/ltc4120.html#demoboards.

| Specification | Without Receiver (Standby) | With Receiver (No Load) | With Receiver (1.58W Load) |

| Operational Frequency | 130.5kHz | 128.7kHz | 128.9kHz |

| Input Voltage | 4.99V | 4.99V | 4.95V |

| Input Current | 0.15A | 0.173A | 0.676A |

| RMS Value of Tx Output AC Voltage | 10.9V | 10.8V | 10.4V |

| Peak Value of Tx Output AC Voltage | 15.2V | 15.2V | 15.2V |

| Receiver Output DC Voltage | N/A | 34.9V | 27V |

| Standby Loss | 0.75W | 0.873W | N/A |

| Efficiency | N/A | N/A | 47.1% |

| Specification | With Receiver (No Load) | With Receiver (1.535W Load) |

| Operational Frequency | 129.5kHz | 128.8kHz |

| Input Voltage | 4.99V | 4.96V |

| Input Current | 0.154A | 0.602A |

| RMS Value of Tx Output AC Voltage | 10.9V | 10.5V |

| Peak Value of Tx Output AC Voltage | 15.2V | 15.2V |

| Receiver Output DC Voltage | 23.9V | 17.5V |

| Standby Loss | 0.768W | N/A |

| Efficiency | N/A | 51.4% |

| Specification | With Receiver (No Load) | With Receiver (1.53W Load) |

| Operational Frequency | 130.2kHz | 128.8kHz |

| Input Voltage | 4.99V | 4.95V |

| Input Current | 0.156A | 0.658A |

| RMS Value of Tx Output AC Voltage | 10.8V | 10.5V |

| Peak Value of Tx Output AC Voltage | 15.2V | 15.2V |

| Receiver Output DC Voltage | 17.4V | 13.9V |

| Standby Loss | 0.77W | N/A |

| Efficiency | N/A | 46.9% |

Figure 7. Battery Charger Power vs Rx-Tx Coil Location.

Figure 8. Typical Battery Charge Profile Using LTC4120 and the Basic Transmitter.

For further information on the LTC4125 AutoResonant Transmitter, please refer to the LTC4125 data sheet at: https://www.analog.com/media/en/technical-documentation/data-sheets/4125f.pdf. The reference design of a wireless power charger system based on the LTC4125 and LTC4120 can be found at: https://www.analog.com/en/search.html?q=dc2386.

Table 5 compares features offered by the various transmitter options.

| Features and Functions | Basic | LTC4125 |

| Rated Power | 2W | 5W |

| Solution | Discretes | Single IC |

| Freedom of Placement | X | ✓ |

| Intelligent Foreign Metal Object Detection* | X | ✓ |

| Low Power Standby** | X | ✓ |

| Optimized Power Delivery/Efficiency at All Power Levels | X | ✓ |

| *This feature is a way of preventing foreign metal objects from heating when they are placed over the transmit coil. | ||

| **This feature allows the transmitter to autonomously enter a low power state when there is no receiver within charging range of a transmitter or if the receiver in range does not require power. | ||