DELIVERING COMPETITIVE EDGE TO OUR CUSTOMERS DELIVERING COMPETITIVE EDGE TO OUR CUSTOMERS

Through Resilient Hybrid Manufacturing

Analog Devices, Inc. (ADI) manufactures over 75,000 analog and mixed signal semiconductor products for 100,000+ customers all over the world in a variety of industries and businesses. Our customer-centric manufacturing organization delivers world-class quality products, and through close partnerships, we help our customers solve their most challenging technology problems. In addition, we help them manage complexity and risk through highly resilient and predictable supply-chain support.

Our resilient hybrid manufacturing strategy is based on a strong network of wafer fabs, foundries, and assembly and test factories that are owned by ADI or its trusted partners. By leveraging our partners’ investments rather than building everything ourselves, we strive to respond rapidly to customer needs and changing market conditions and focus our investments on innovative manufacturing solutions.

“Founded decades ago by two MIT grads, Analog Devices finds innovative solutions to today’s biggest challenges. By collaborating with companies like Analog, we’ll make Massachusetts a hub for semiconductor and chip innovation and manufacturing.”

Maura Healey, Massachusetts Governor

Source: Patch.com

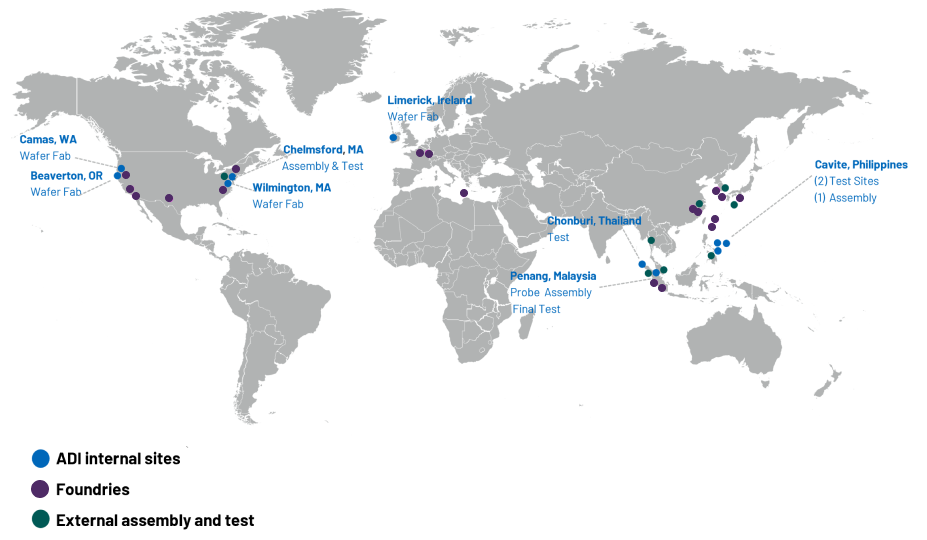

Resilient Hybrid Manufacturing Network

ADI’s resilient hybrid manufacturing network is built to quickly add manufacturing capacity and balance customer demand between our internal factories and external partner foundries. This flexible hybrid network insulates ADI from external factors while providing the means to increase output and scale rapidly to meet customer needs.

Our network consists of 10 internal factories and 50 supply chain factories across 15 countries, supported by approximately 24,000 ADI employees. ADI qualifies and matches manufacturing processes across our supply chain so that we have flexibility around where to manufacture our industry-leading semiconductor products. ADI’s strong partnerships, based on years and sometimes decades, deliver the supply and expertise required for a resilient and flexible supply chain that supports quicker time to production for our customers.

Expanding for the Future

Front-End Operations

We are expanding fab capacity, internally and externally, with internal investments supporting double the output in the U.S. and Europe by the end of 2025.

In Beaverton, Oregon, we are increasing our cleanroom by 25,000 square feet to double capacity and converting it to a full 8-inch fab. In Limerick, Ireland, we are expanding our footprint by 15,000 square feet to triple capacity. In Camas, Washington, we are investing to double our capacity.

Back-End Operations

ADI does most test operations in our own factories in the Philippines, Malaysia, and Thailand, and outsources assembly to trusted partners. To add resilience to our large operations in the Philippines, we are expanding our test facilities in Malaysia and Thailand as well as implementing a multi-year campus expansion in the Philippines to add office space for an expected addition of 2,000 employees and more engineering capabilities. Additionally, we are cross-qualifying our test processes with external partners to ensure dual sourcing where needed.

“Right now, you’re seeing us expand internally at all of our sites, bringing back these jobs we desperately need for manufacturing… and more opportunities to have cutting-edge technology like this [ADI chip used in NASA’s Mars rover] in a wide range of industries that we serve.”

John Michael, General Manager of Global Operations and Technology

Analog Devices

Source: The Columbian

Manufacturing Flexibility

Analog Devices leverages multiple factories running the same technologies in different countries, never just in one geographic area. Our diverse global network runs legacy and new processes in both internal and trusted partner fabs, delivering a broad array of technology and packaging necessary to create innovative solutions from 7 nanometers to 7 microns. This strategy improves our flexibility and helps ADI efficiently manage operations through economic cycles.

Today, Analog’s Limerick wafer fabrication facility is one of the most important success stories in the company’s 50-year history. It employs over 1,200 scientists, engineers, production and support staff in one of the largest, most successful, most technologically advanced campuses in the country and has achieved a sustained stream of world-class innovative new products, profitability, and growth.

THE FUTURE YEARS: A STORY OF ANALOG DEVICES’ START-UP IN LIMERICK by Pat Cunneen

Source: Limerickslife.com

World-Class Quality

Ensuring top quality and reliable products for our customers is our top priority. Analog Devices is committed to the establishment and continuous improvement of world-class systems and processes aimed at satisfying our customers' evolving needs. We embrace a Total Quality philosophy with an emphasis on prevention rather than detection. Read more about our quality philosophy, processes, and awards here.

Sustainability

As Analog Devices CEO Vincent Roche has stated, “ADI has worked tirelessly to maintain and enhance supply chain resilience in response to record semiconductor demand.” Even in light of doubling our internal manufacturing production, Analog Devices is committed to reaching our climate, water, and waste reduction goals. Our current plans are driving us to an estimated 75% reduction in Scope 1 and 2 greenhouse gas emissions by the end of 2025. We set goals to become carbon neutral by 2030 and achieve net zero emissions by 2050 or sooner. We recycled 23 percent of the water we used in 2021 and have set a goal to increase that proportion to 50 percent in 2025. Similarly, 39 percent of the energy used at our manufacturing sites came from renewables last year, and we intend to increase that to 100 percent by 2025.

Learn More

Gain more insight into how ADI’s resilient hybrid manufacturing network provides the flexibility needed for both ADI and our customers.

Explore some of ADI’s global opportunities

See what it’s like to work and make a difference in ADI Limerick.

Learn about the exciting careers at ADI Beaverton, Oregon

Forward-Looking Statements

This website contains forward-looking statements, which address a variety of subjects including, for example, our statements regarding expanding manufacturing capabilities, fab capacity, footprint, test facilities and output; adding employees; expanding engineering capabilities; goals, commitments, programs, timelines, targets, initiatives and objectives relating to climate, including our goals to become carbon neutral and achieve net zero emissions, and energy, water, emissions reductions, recycling and waste usage; and managing our operations through future economic cycles, supply chain resilience; and other future events. Statements that are not historical facts, including statements about our beliefs, plans and expectations, are forward-looking statements. Such statements are based on our current expectations and are subject to a number of factors and uncertainties, which could cause actual results to differ materially from those described in the forward-looking statements. For additional information about factors that could cause actual results to differ materially from those described in the forward-looking statements, please refer to our filings with the Securities and Exchange Commission (“SEC”), including the risk factors contained in our most recent Annual Report on Form 10-K, Quarterly Report on Form 10-Q, and other filings with the SEC. Forward-looking statements speak only as of the date they are made, and we do not undertake any obligation to update any forward-looking statement.