Digital Enterprise—Intelligent Data from the Edge Digital Enterprise—Intelligent Data from the Edge

Explore Intelligent Edge Application Use Cases from ADI

Empower the Intelligent Edge with Next-Generation Field Instruments

Advances in measurement, processing, security, connectivity, and power management technologies are enabling the development of more intelligent field instruments, enabling data-driven insights and the digital transformation of the process industry. As a cocreation partner of choice, Analog Devices creates key enabling technologies to access new data, unlocking insights to improve product quality, increase productivity, lower maintenance costs, reduce energy consumption, and avoid unplanned downtime.

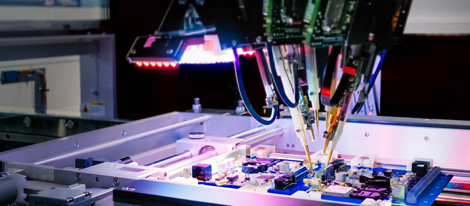

Embrace the Digital Enterprise with Smart Factory Sensors

Smart factories require intelligent sensors and actuators that facilitate better decision making, enabling more flexible and readily optimized manufacturing processes. Analog Devices IO-Link® technology enables traditional sensors to become intelligent sensors, removing the need to retrofit new sensor technology to achieve a real-time configurable factory floor. ADI’s portfolio of high precision analog converter, linear, and signal conditioning products offers solutions to match the performance, power, cost, and size requirements for smart sensor analog front ends.

Elevate Surveillance with Cameras That See, Sense, and Think

In industrial and commercial environments, heightened surveillance can enhance worker safety, add quality control, and control access to critical assets—but new, integrated technologies are needed to make these capabilities a reality. Analog Devices offers the core technology and execution expertise to enable cameras to see, sense, and think at the intelligent edge.

Access Data and Capture New Insights with Plant-Wide Connectivity

Industrial connectivity technology gives central control rooms access to the vast volume of data being created across intelligent buildings and factory floors, enabling remote asset management, centralized planning, and real-time diagnostics. The first step toward a digital enterprise is connecting previously unconnected field devices or assets.

Engineering an intelligent, connected automation environment where all equipment seamlessly collect and share information is central to the IIOT vision. The challenge becomes interconnecting all the devices across the enterprise and enabling both real-time and nonreal-time traffic to coexist. This requires low latency, deterministic, low power, robust industrial connectivity technology to unlock the intelligent edge. Understanding the choices available and identifying the best technology is essential to future-proofing the network architecture.

ADI is a Trusted Partner for Industrial Connectivity Technologies that Drive Factories of the Future

Industrial Ethernet

- Lowest latency, lowest power Ethernet

- Complete communication platforms

- Scalable solutions

Serial Connectivity

- Isolated and nonisolated RS-232, RS-485, and CAN transceivers

- Compact ease of use USB port isolators

- Enhanced robustness

5G

- Best-in-class 5G radio technology

- Full signal chain capabilities

- Ultrareliable low latency and low power

Robust, Secure Connectivity for Long-Term Reliability

The connected factory contains a large volume of nodes to connect, and each node is responsible for transmitting critical control traffic commands. Therefore, a highly robust industrial connectivity solution is needed to create a network you can count on. ADI, as a pioneer in edge device security, is a trusted ally in ensuring secure boot, updates, and device authentication.

Learn how cyber security technology from ADI is helping to secure the edge where data is born.