Building a Better Stepper Motor System with StallGuard and CoolStep Technologies

Sensorless technologies like StallGuard™ and CoolStep™ reduce safety margins and increase energy efficiency using the naturally generated back EMF of a motor. These fully integrated building blocks increase reliability and efficiency for stepper motors and improve user experience by enabling additional functions like sensorless homing without extra cost.

How StallGuard and CoolStep Technologies Take Advantage of Back EMF

A motor can be used just like the dynamo of a bike: Turn the motor and it generates electromotive force, or EMF, which can be measured through the sense resistors. The difference between electrical energy flowing into and out of the motor offers insight into motor current and load angle, which can help drive performance improvements. The spare energy that goes back from the motor to the power supply (back-EMF) is a measure for the mechanical load applied to the motor, or the load-angle. When the load angle is zero, there’s no spare energy left, and the motor may stall.

StallGuard Technology: From Sensorless Homing to Smart Stall Response

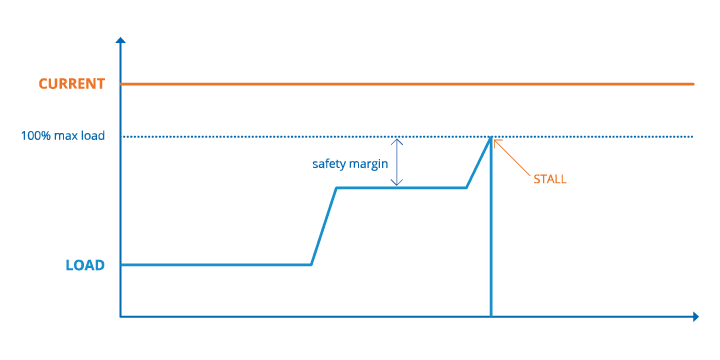

StallGuard technology is a sensorless load measurement for stepper motors that gives cost-effective feedback on the load-angle. The StallGuard sensitivity can be adjusted to fit the application’s need, making it ideal for sensorless homing, self-calibration, distance measurement, or verifying that all mechanics are functioning within the safety margins.

Implemented in a standard stepper motor driver, the sensorless load detection eliminates the need for reference or limit switches and reduces the cost and complexity of applications where precise referencing is required.

Normally, open-loop stepper drives lose step count in overload situations as they stall, for example when an axis is obstructed. StallGuard technology can prevent step loss by stopping the motor when the set load value is reached. The sensorless technology can detect up to 1024 different load levels, enabling high resolution feedback for continuous monitoring of the system.

CoolStep Technology: An Arsenal of Stepper System Efficiencies

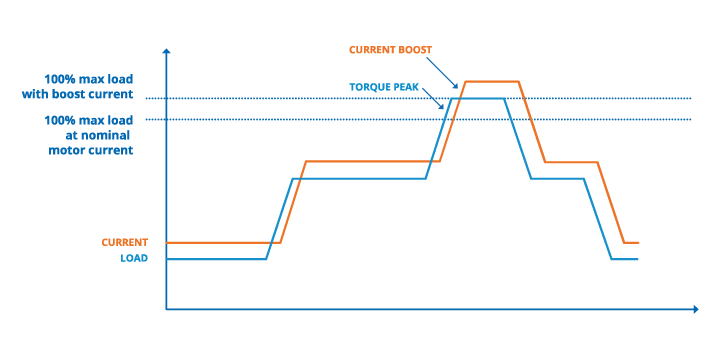

CoolStep technology offers dynamic current control based on StallGuard values. It identifies excess energy that is not being used in the drive system to minimize energy fed back from the motor to the power supply and improve drive system efficiency. Originally developed for medical devices and lab automation, the sensorless load-dependent current control always drives the motors at the minimum amount required for the actual load condition, reducing motor energy consumption by up to 90% with StallGuard 4 and up to 75% with StallGuard 2. Moreover, CoolStep technology reduces heat generation, adding to its repertoire of efficiencies.

By eliminating the current safety margin and allowing for temporary current boosts, CoolStep technology can also allow for smaller motors since less torque reserve is required.